Autoclaves

Why 316 stainless steel Is the gold standard for autoclaves

Jan 08 2026

Autoclaves operate under some of the most demanding conditions found in laboratory, healthcare, and industrial environments. Subjected to repeated cycles of extreme temperature, pressure, and humidity, they must perform reliably day after day to ensure effective sterilisation and safe operation. Such harsh and fluctuating conditions place exceptional stress on materials, increasing the risk of corrosion, pitting, cracking, or long-term distortion if inappropriate construction materials are used. It is for this reason that material selection is not simply a design preference, but a critical determinant of an autoclave’s performance, longevity, and total cost of ownership.

Stainless steel has long been the material of choice for autoclave manufacture, largely due to its inherent corrosion resistance. All stainless steels contain chromium, which enables the formation of a passive, self-healing oxide layer on the surface. This invisible barrier protects the metal beneath from oxidation and corrosion when exposed to moisture and oxygen. However, not all stainless steels are created equal, particularly when it comes to the uniquely aggressive environment generated by steam sterilisation.

Type 316 stainless steel distinguishes itself through the addition of molybdenum to its alloy composition. This element significantly enhances resistance to pitting and crevice corrosion - forms of localised attack that commonly occur in wet, chloride-rich conditions. Steam sterilisation environments, characterised by high humidity, elevated temperatures, and the presence of dissolved salts, are particularly conducive to such corrosion mechanisms. Over time, these can compromise both performance and safety if inferior materials are used. The enhanced corrosion resistance of 316 stainless steel makes it especially well-suited to autoclave pressure vessels and internal components, where long-term durability is essential.

For these reasons, 316 stainless steel remains the manufacturing material of choice for all autoclaves produced by Priorclave. Laboratories and facilities seeking robust, reliable, and long-lasting sterilisation solutions should regard the use of 316 stainless steel not as an optional upgrade, but as a fundamental requirement.

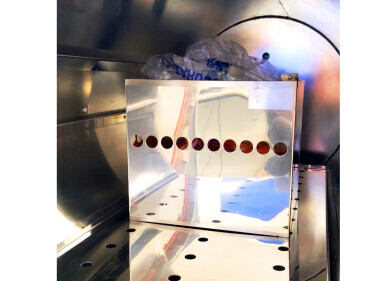

Material selection alone, however, is only part of the equation. Equally important is manufacturing control and quality assurance. Priorclave is one of the few autoclave manufacturers globally to retain complete control over its entire supply chain. All principal components - including pressure vessels - are fabricated in-house at its South East London facility. This vertical integration allows Priorclave to guarantee the consistent use of certified 316 stainless steel throughout its product range, while maintaining rigorous standards of workmanship and traceability.

Choosing the right 316 stainless steel autoclave ultimately depends on the specific requirements of each laboratory or facility. Load types, throughput, available space, and sustainability goals all play a role in determining the most suitable solution.

Among Priorclave’s most widely adopted models is the EV100 BASE. Occupying less than one cubic metre of laboratory space, it offers an impressive chamber capacity relative to its compact footprint. Its enduring popularity stems not only from its robust 316 stainless steel construction and proven reliability, but also from its ability to accommodate very tall labware and vertically oriented loads - an important consideration for many research applications where flexibility is essential.

For laboratories requiring enhanced performance, the EH150 SMART stands out as one of Priorclave’s most popular front-loading autoclaves to date. Like all models in the SMART range, it is vacuum equipped, enabling efficient sterilisation of porous or challenging loads. Its optimum loading height improves ergonomics and safety, while its economical use of power and water helps minimise both environmental impact and operating costs. The EH150 SMART is ideally suited to laboratories processing up to five loads per day, offering an excellent balance between performance, efficiency, and sustainability.

At the higher end of throughput requirements, the SH450 RSC PERFORMANCE is designed for demanding research, education, industrial, and quality assurance environments. Both steam-jacketed and vacuum-equipped, it delivers faster cycle times and greater flexibility when handling a wide variety of complex loads. Its construction and capability make it particularly well-suited to facilities where uptime and throughput are critical.

To further enhance longevity and hygiene, Priorclave treats the external surfaces of its BASE, SMART, and PERFORMANCE ranges with an antimicrobial epoxy coating. Tested to ISO 22196:2011 standards, this coating contains nano-silver particles that provide durable, lifelong protection against microbial contamination. Importantly, the coating cannot leach or be washed away, ensuring continued effectiveness throughout the autoclave’s operational life. In busy research spaces, shared facilities, and teaching environments - where cross-contamination is an increasing concern - this additional layer of protection offers valuable reassurance.

Control across the range is provided by Priorclave’s exclusive Tactrol®3 control system. Designed to combine precision with ease of use, it allows accurate cycle programming while remaining intuitive, even when operated with gloved hands. Features such as Delayed Start and Media Warming are particularly valued in research settings. These functions allow growth media to be sterilised overnight and held at optimal dispensing temperatures, reducing the risk of thermal degradation, caramelisation of high-glucose formulations, or boil-over events. As a result, media can be prepared overnight and ready to pour at the start of the working day - improving efficiency without compromising quality.

In an environment where reliability, safety, and longevity are paramount, 316 stainless steel continues to set the benchmark for autoclave construction. Combined with in-house manufacturing expertise, advanced control systems, and thoughtful design, it remains the gold standard for facilities that demand uncompromising performance.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh