Autoclaves

How to Load an Autoclave for Liquid and Media Cycles

Nov 19 2025

So, you have your autoclave, and you have some bottles of liquid. The sterilisation process is simple, right? Put the bottles into the autoclave and run it. To some degree this is true, but correctly loading an autoclave with liquids is a key step to ensure that sterilisation is effective, energy efficient, and that it results in liquid that is usable for its intended purpose post-sterilisation.

The Load

Start with suitable bottles, such as Duran-type laboratory bottles, all of the same size and filled with similar volumes of liquid, for example around 300 mL each. Keeping both bottle size and fill volume consistent means they will heat at roughly the same rate. If one bottle is much larger or much fuller than the others, it will lag behind and may not be properly sterilised even though the cycle appears complete.

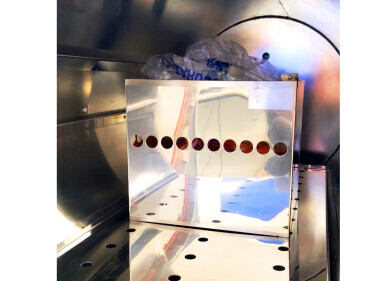

When placing the bottles in the chamber, ensure there is space between them. You want air gaps to allow steam circulation and air removal. Steam must penetrate all around each vessel so the whole load can warm up evenly. Avoid tightly packing bottles together or pressing them against the chamber walls.

Many autoclaves use a load probe (also called a load sense timing probe or LST probe) to monitor the temperature inside a representative vessel – this is a feature that you should certainly look for when selecting an autoclave for sterilising liquids. Ideally, one bottle lid should have a hole that allows you to insert the load probe into the liquid. This bottle then becomes the control bottle, giving a true reading of the product temperature rather than just the chamber temperature.

Be careful with mixed loads. If you put small bottles and large bottles together but place the probe in a small bottle, that bottle will reach 121 °C first and the autoclave will start timing while the larger bottles are still cooler. Those larger volumes may be under-sterilised. If you move the probe to the largest bottle, the small ones will become over-sterilised or “overcooked”. For reliable results, keep liquid loads as uniform as possible and always put the probe in the slowest-heating item if you must mix sizes.

The Process

A modern autoclave will be pre-programmed with a series of cycles to process a variety of materials. Most will include a liquid cycle designed for the specific task of sterilising liquids.

During the cycle, the autoclave first goes through a free-steaming stage at around 100 °C. This part of the process does two things: it drives air out of the chamber and helps the load temperature catch up with the chamber temperature. Once this stage is complete, the valve closes and the autoclave increases pressure and temperature to a typical sterilisation set point, often 121 °C for 15 minutes.

Because the load warms more slowly than the metal chamber, the autoclave may briefly overshoot the chamber temperature (for example up to about 123 °C) to help the liquid reach 121 °C more quickly. Once the load probe detects that the liquid has reached the target temperature, the controller adjusts and holds the chamber slightly above the set point so the load stays at or above 121 °C for the full sterilisation time.

Finally, allow the load to cool safely. Many systems cool naturally to just above 100 °C before fans assist. You must not open the door until the load temperature (not just the chamber) has dropped below about 80 °C. At that point, wearing heat-proof gloves and appropriate face protection, you can remove the bottles safely.

More advanced autoclaves will be fitted with components to increase cooling – and therefore overall processing – speeds, such as chamber cooling jackets and in-chamber fans. Where these are used, an air-ballasting system is also required to counteract the rapid pressure drop inside the chamber as it quickly cools. If this system is not fitted, the liquid can boil and bubble out of the bottle in the reduced pressure environment.

Finding the Perfect Setup

To test your load layout and find a replicable setup that ensures all liquids within the load are sterilised in the most time- and energy-efficient manner, it is possible to validate the specific load. During this process, setups are tested and temperatures are measured across a number of bottles within the load to ensure that the correct temperatures are reached throughout. As a UKAS-accredited autoclave validation laboratory, Astell Services provides load validation services for Astell autoclaves throughout the UK.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh