Autoclaves

Drier loads that save time, energy, and reprocessing

Jan 09 2026

One of the worst things you will encounter after running a sterilisation cycle in your autoclave is evidence of moisture, either within the chamber or, worse, the load itself. Wet loads are a common cause of contamination because excessive moisture can act as a pathogen pathway and cause recontamination of your sterilised instruments and equipment.

A ‘wet pack’ refers to any load that comes out of the autoclave problematically damp. The term originates in medical settings, where it usually refers to wrapped instruments that have visible moisture on or inside the pack after sterilisation.

Wet packs are a huge concern for hospitals’ sterile services departments, dental offices and medical clinics globally. In a medical setting, no wet pack can be trusted, and every wet pack should be treated as a serious red flag, because moisture can create a pathway for microorganisms to contaminate sterile loads.

In most research and industrial labs, although potentially less of a concern. Wet loads are still both an inconvenience and an increased risk of contamination, which can threaten the validity of research or testing.

In most labs, wet loads can usually be traced back to one or more of these three common causes:

- Improper loading: Good sterilisation requires good steam circulation in the autoclave chamber. Just as overloading can trap cold air pockets, it can also trap steam. That steam will condense and pool in the load, rather than draining away at the end of the cycle

- Autoclave issues: This includes problems with the steriliser itself (e.g., poor steam quality—especially in systems relying on house steam or an external steam generator—or malfunctioning drains and vents) and with the programming (e.g., incorrect settings when running the cycle)

- Incorrect handling: Opening the autoclave too soon or unloading items before they have had adequate time to cool will encourage condensation to form on the load

With a little care, you’ll find it pretty easy to avoid wet packs and produce drier loads in the lab.

How to avoid wet packs in the lab

There are four things any autoclave user can do to ensure they end up with the driest possible finished loads:

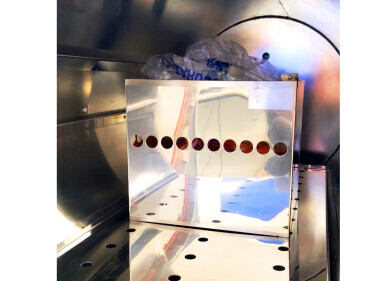

- Load carefully: Always load your autoclave with an eye toward steam and air circulation and keeping vents and drains clear.

- Choose the right cycle: Make sure you are running a cycle with a ‘Post-cycle vacuum’ stage. This evacuates the chamber at the end of the cycle, taking a great deal of residual moisture with it, and speeding evaporation. That said, a vacuum alone cannot reliably result in completely dry loads. For that you need to apply additional heat to the chamber at the end of the cycle, usually via an integrated external heat jacket or heater mats.

Warning: vacuum cycles are strictly for non-liquid loads. If you pull a post-cycle vacuum on flasks holding liquid media, they’ll likely boil over or burst!

- Perform regular maintenance: Wet loads are generally the result of steam lingering too long in a cooling chamber. The culprit is often a partially obstructed drain or vent. Regular maintenance will prevent that from becoming a problem. If the maintenance schedule looks daunting, perform what is known as a ‘dynamic air removal test’ or ‘Bowie-Dick test’. This will confirm that your steriliser is properly pulling and holding a vacuum, and thus can effectively clear steam from the chamber at the end of the cycle.

To perform the test, place a specialised indicator pack in an empty pre-warmed autoclave (usually over the drain), run a pre-vacuum cycle, and then examine the indicator for a uniform colour change, indicating successful steam penetration and air removal, with non-uniformity signalling a failure requiring investigation.

- Dry and store sterilised items properly: A load of lab glassware fresh out of the autoclave is like a load of dishes fresh out of the dishwasher: items are hot, and likely have trapped some moist air (especially in narrow-mouthed flasks or long narrow tubes). Tightly stacking or packing these items in sealed cupboards can lead to condensation, potentially creating an environment for microbes to colonise. A lab drying cabinet can be extremely useful if you don’t have the luxury of allowing loads to fully dry before unloading the autoclave.

Optimise lab efficiency with Priorclave

Budgets are tight, and resources are valuable. The last thing you need is to waste time, water, and electricity re-running sterilisation cycles. At Priorclave, our goal is to make sure labs of all sorts run as smoothly as possible. That means lab techs can spend more time doing their work and less time worrying about their equipment. At Priorclave, we build each autoclave to order, ensuring it has the right combination of features to help you get the job done with as little hassle as possible. Contact Priorclave direct, whenever you’re ready to discuss what combination of features will serve you best.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh