News

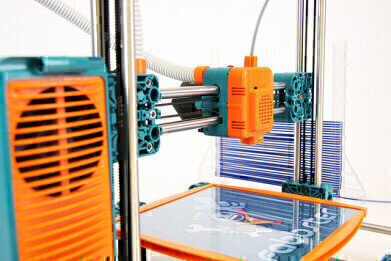

How Does 3D Medicine Work?

Sep 15 2015

The pharmaceuticals industry turned over a new leaf earlier this month when the US Food and Drug Administration gave the go-ahead for production of a 3D-printed pill. The step marked the emergence of ‘3D medicine,’ a new term that will categorically shape the future of pharmaceuticals. Intrigued? You’re not alone. The approval made global headlines however not everyone is 100% clear on what 3D medicine means, and how it will impact the pharmaceuticals industry as we know it. Here’s our explanation:

Not an entirely new concept

While the concept of 3D medicine is new, the use of 3D printers to manufacture approved medical devices isn’t. In the past the machines have been used to create FDA approved prosthetics, dentistry implants and more.

The ‘ink’ is substrate and substance

Rather than use plastics, polypropylene or other industrial materials to create medication, pharmaceuticals companies have been using layer upon layer of active ingredient.

The company behind the development of the world’s first 3D pill is US based enterprise, Aprecia Pharmaceuticals. It used 3D printers to create Spritam pills, a medication used to control seizures brought on by epilepsy. It works exactly the same as conventionally manufactured medicine, with the pills dissolving in the mouth and releasing active ingredients. The only real difference is the efficiency in which the medicine is produced.

The benefits of going 3D

For both pharmaceuticals companies and the patients they service, 3D medicine offers a myriad of benefits. Drugs are printed in layers which allows manufacturers to tightly pack in more precise doses of active ingredients. For example, Aprecia Pharmaceuticals was able to cram 1,000 milligrams of Spritam into each individual pill!

Industry experts have also hailed 3D medication as an affordable solution for personalising medicine. Using 3D printers medical institutions will be able to manufacture bespoke dosages tailored to suit the individual needs of patients. With just one tweak to the printing specifications operators will be able to inexpensively adjust doses in a matter of seconds. Dr Mohamed Albed Alhnan, a pharmaceutics lecturer at the University of Central Lancashire says, “For the last 50 years we have manufactured tablets in factories and shipped them to hospitals and for the first time this process means we can produce tablets much closer to the patient."

Could human cells be the next big thing to hit the 3D printing sector? ‘Miniature VHS Solenoid Valves Play Significant Role in the Viability of 3D Bio-Printing of Human Cells’ sheds fascinating light on the rapid development of viable inkjet technology for highly specialised applications, including printing human cells. The technology is known as ‘biofabrication’ and could potentially replace the highly controversial process of testing new drugs on live animals.

Images sourced via Flickr Creative Commons. Credits: Creative Tools

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh