Mixers

Laboratory-scale In-Line Mixers from Silverson Machines

Mar 06 2025

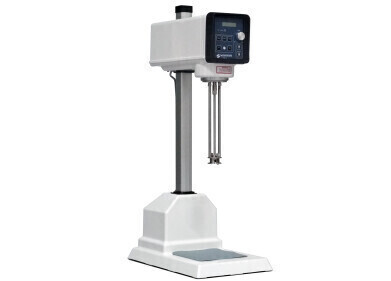

Silverson Machines offers a range of laboratory-scale bench top In-Line mixers ideal for laboratory or pilot scale applications. These mixers deliver consistent performance, uniform results and aeration-free operation as well as excellent reproducibility when scaling up.

The Silverson Verso provides an accurate and easy means of forecasting the performance of larger In-Line mixers under full-scale working conditions. The mixer is equipped with a digital tachometer, ammeter and programmable timer, invaluable for applications where process validation and reproducibility are required. The Verso is able to achieve self-pumping throughputs of up to 2,400 litres per hour.

The mixer works under the same principles as the larger, full-scale In-Line mixers in the Silverson product range; the high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly.

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.

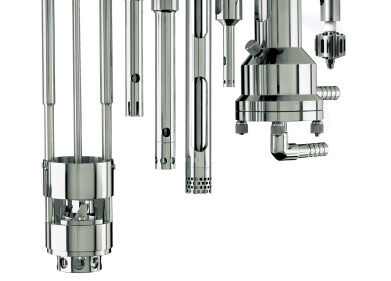

The Verso can be used for a wide range of mixing operations including emulsifying, homogenising, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. It is able to complete all of these mixing tasks due to the comprehensive range of interchangeable workheads and screens available with the mixer. Single-stage rotor/stator configurations are standard, but the Verso can be supplied as a multistage unit, which increases the number of shearing actions per revolution of the rotor, resulting in substantially faster mixing times and increasing the number of products that can be processed in a single pass.

The Verso can be supplied with a Vessel package comprising a 20 litre stainless steel vessel, vessel stand, pipework and valve.

In addition to the standard model, the Verso range includes two additional models:

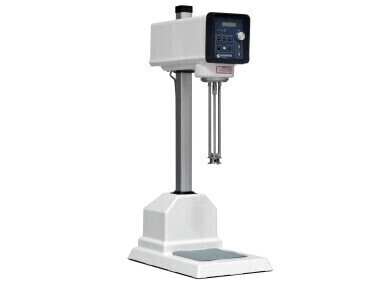

Verso UHS: An Ultra-Hygienic version of the standard model, the Verso UHS is designed for stringent applications in the Pharmaceutical and Biotechnology industries as well as Food, Cosmetics and other clean industries.

Verso-UHS-HV: The Verso-UHS-HV is designed for mixing high viscosity products. It incorporates the same unique and innovative ‘pumping rotor’ design as the production scale UHS-HV In-Line mixers. This substantially increases its self-pumping capacity, allowing it to process products such as gels, creams, sauces and gum solutions on a laboratory scale.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh