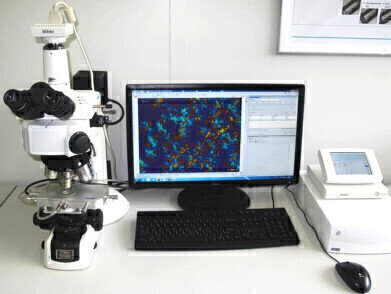

Laboratory microscope

Versatile Temperature Stage used for crystallisation studies on Semi-Crystalline Polymers

Sep 14 2013

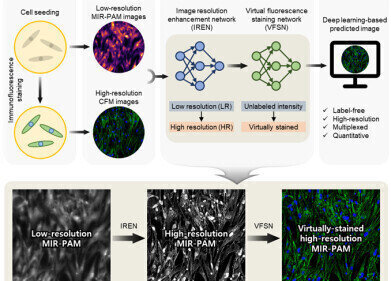

Linkam Scientific Instruments report on the use of their functional LTS420 temperature stage for crystallisation studies at the Technische Universität Kaiserslautern.

PhD candidate, Mr Buncha Suksut MSc, is completing his studies at the Department for Composite Engineering at the University. His work focuses on the morphology development and micro-/nanoscopic deformation behaviour of thermoplastic materials reinforced on the nanoscale.

Mr Suksut commented: "The study of the microstructure development during crystallisation of semi-crystalline polymers can be performed by using the LTS420 hot stage and polarised light microscopy. The final mechanical properties of semi-crystalline polymers strongly depend on the morphology which is governed by the respective processing and crystallisation process."

The LTS420 hot stage is an easy to use, versatile heating and freezing stage optimised for isothermal sample analysis applications where high speed heating and cooling are compromised by larger sample area. The stage has an excellent thermal stability of less than 0.1°C. The stage consists of a large area temperature controlled element with a platinum resistor sensor embedded close to the surface for accurate temperature measurements. The sample is simply mounted on a standard microscope slide in direct contact with the heating element and can be manipulated 15mm in X and Y directions. The sample chamber has gas valves to purge with either inert gas or humidity.

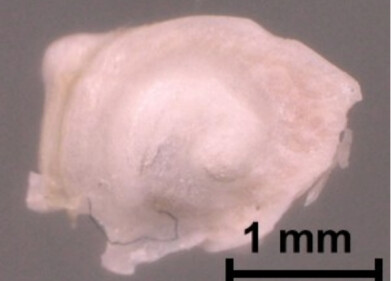

Mr Suksut explained: "The aim of my study is to characterise the crystallisation of polymers by using polarised light optical microscopy. Because the crystallisation of a polymer starts at high temperature, we are using the hot stage to generate the heat. We have equipped the microscope with the hot stage to observe the crystallisation during heating/cooling processes. The specimens are heated up to a certain point above the melting temperature and then cooled down with a defined cooling speed. During cooling, images are captured using a digital camera. From these results, the spherulitic growth rate can be calculated by measuring the radius of spherulite as a function of time. Our research activities focus on the crystallisation behaviour of particle filled semi-crystalline polymers. By using the method we discovered that some nano-sized particles facilitate the crystallisation resulting in shorter cycle-times in processing."

Digital Edition

Lab Asia 32.2 April

April 2025

Chromatography Articles - Effects of small deviations in flow rate on GPC/SEC results Mass Spectrometry & Spectroscopy Articles - Waiting for the present to catch up to the future: A bette...

View all digital editions

Events

Apr 09 2025 Tokyo, Japan

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Analytica Anacon India & IndiaLabExpo

Apr 23 2025 Mumbai, India

Apr 23 2025 Moscow, Russia

-(3).jpg)