Autoclaves

How do Autoclaves Work?

May 07 2015

Unless you work in an environment where autoclaves are used regularly, you may not be familiar with autoclaves. Some of you might be familiar with them as a sterilisation instrument in hospitals. However, if you've ever done a little bit deeper into this topic, you’d know how grateful we should be for the existence of these machines. In a world teeming with bacteria they are crucial!

So how do autoclaves work?

Are you familiar with pressure cookers? You may not have used one or seen one being used, because they were largely superseded by microwave ovens form the 1980s onwards, but they were all the rage before that. They were heavy saucepans with heavy lids that actually sealed the pan, rather than just covered it. The pan contained water (and food of course) and because the steam couldn't escape the pressure increased. The water boiled at a much higher temperature than normal and the food was therefore cooked much faster than in a normal saucepan. There was a safety valve on top of the lid, by the way, to allow some of the steam to escape and prevent an explosion spoiling your food and your day in general.

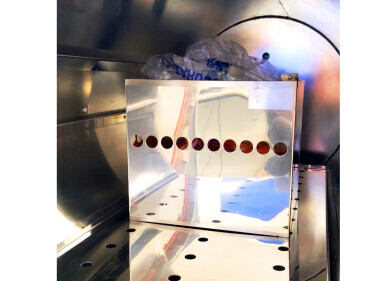

Autoclaves work in much the same way. An autoclave is essentially just a large steel vessel through which steam is circulated to sterilize things, perform scientific experiments, or carry out industrial processes to blast things with steam long enough to kill any germs and therefore sterilise the objects. As with the pressure cooker, the extra pressure in an autoclave means that water boils at a temperature around 20% higher than the usual boiling point, so is very effective at penetrating and sterilising things.

For information on autoclaves in a laboratory environment read: Ins and Outs of Autoclaves in a Sterile Lab.

More detail…

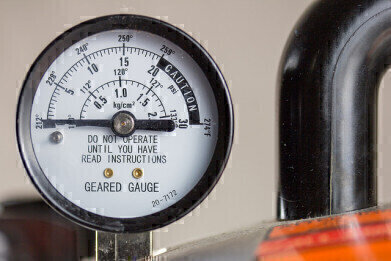

Once the autoclave chamber is sealed, the air is removed from it either by a vacuum pump or by pumping in steam to force the air out. Next, high pressure steam is pumped through the chamber so it reaches a temperature of about 121–140°C (250–284°F). A thermostat then starts a timer and the steam pumping continues for long enough to kill most micro-organisms. The exact sterilizing time depends on a variety of factors but is generally somewhere between 3 and 25 minutes.

So, as mentioned earlier, autoclaving is a bit like pressure cooking – and the pressure matters as much as temperature and the time, or even more so. Sudden release of pressure can cause an explosion, so great care must be taken when opening the autoclave on completion of its cycle.

Where can I purchase an autoclave?

If you’re purchase an autoclave, take a look at our Buyer’s Guide.

Image Source: Autoclave Gauge

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh