-

Those dealing with large volumes of liquid waste benefit from a different method of sterilisation.

Those dealing with large volumes of liquid waste benefit from a different method of sterilisation.

Autoclaves

How to manage large quantities of contaminated liquid lab waste

Sep 18 2025

Disposing of large volumes of biologically contaminated, potentially infectious liquid is easy. Just pour it down the drain as soon as it is created. Simple. The problem is gone. That would be nice, but the competent and competent lab manager knows pathogenic waste needs sterilizing before release into the wider environment, as to mitigate risk. Yet the dream of a simple pour-away-process is achievable by the integration of hardware into a lab’s wastewater steam.

Compared with solid materials, contaminated liquid waste poses a greater challenge to laboratory managers. Liquids are inherently mobile and can contain contaminants throughout their volume, not just on the surface. As a result, laboratories often aim to minimise liquid waste production, keeping volumes small enough to sterilise with a standard autoclave. However, certain processes inevitably generate large volumes of liquid waste — making sterilisation by autoclave alone more complex.

To take arms against a sea of (pathogenic) troubles…

Autoclaves are not inherently challenged by sterilising large liquid volumes, but the problem lies in the logistics of getting contaminated liquid into the device — and sterile liquid out. Even with specialised handling and loading equipment, the process can be cumbersome, time-consuming, and risky, with potential hazards during ingress (biohazard exposure) and egress (handling heated liquids).

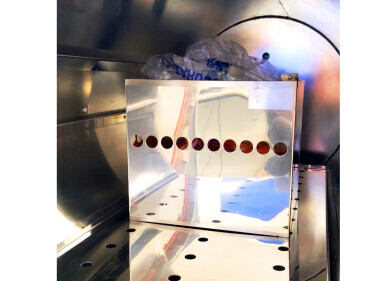

The nature of liquid waste — both “liquid” (highly mobile) and “waste” (requiring disposal) — provides the opportunity for a different type of autoclave. One without a door, without the need to manually load or unload large volumes of liquid, and therefore without the handling risks. Enter the Liquid Waste Autoclave (LWA) and the Thermal Effluent Decontamination System (TEDS).

…and by automated thermal sterilisation, end them.

Instead of a door, LWAs and TEDSs use liquid entry and exit valves to control access to, and seal, the sterilisation chamber. Contaminated waste enters, is sterilised under heat and pressure, and then discharged directly to the sewer — all as part of a fully automated process. The sterilisation method is identical to that of a standard autoclave, with one distinction: instead of using steam to carry thermal energy, the liquid waste itself is heated directly to sterilising temperatures under pressure.

The main difference between LWAs and TEDSs is capacity. LWAs are compact systems designed for laboratory use, with terminology familiar to staff already accustomed to autoclaves. TEDSs, by contrast, are large-scale systems capable of processing wastewater from entire facilities, handling thousands of litres at a time.

Practical solutions for laboratories and facilities

AstellBio offers a wide range of LWAs and TEDSs designed to sterilise wastewater — from systems handling just tens of litres per hour to those capable of thousands. Available as both off-the-shelf and customised solutions, these technologies support organisations across biotechnology, clinical, pharmaceutical, and horticultural sectors, among others, providing safe, reliable, and fully automated disposal of contaminated liquid waste.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh