-

Improve autoclave safety, reliability and performance with this expert guide for lab professionals

Improve autoclave safety, reliability and performance with this expert guide for lab professionals

Autoclaves

10 essential autoclave maintenance tips for laboratory technicians in 2025

Jul 15 2025

Proper autoclave maintenance is vital for ensuring sterilisation efficiency, equipment longevity and laboratory safety. Whether you are a biomedical scientist, lab technician or facility manager, following best practices can reduce downtime and extend the life of your autoclave. These ten expert-backed autoclave care tips will help you maintain compliance and ensure optimal operation.

Respect autoclave pressure limits

Autoclaves operate under high-pressure steam and must be handled with caution. Never force the locking mechanism, and do not use the unit if you detect leaks, hissing or damage. Always follow the manufacturer’s operating manual and report any irregularities immediately.Maintain a digital or paper logbook

Accurate record-keeping is essential. Keep a dedicated autoclave maintenance log to track inspections, faults and scheduled servicing. Check recent entries before each cycle to flag unresolved issues or patterns that may require attention.Select the correct sterilisation cycle

Using the wrong programme can lead to incomplete sterilisation. Choose the correct pre-set cycle based on load type – eg., glassware, waste, liquids – this ensures both effective decontamination and energy efficiency.Use the Load Probe correctly

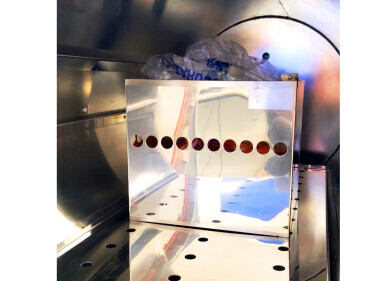

If your autoclave is equipped with a Load Probe, use it consistently. Place it inside a Duran bottle filled with an equivalent volume of water to your load. Ensure the probe is positioned the same way each time to obtain accurate internal temperature data.Load the autoclave chamber properly

Overloading restricts steam flow and leads to sterilisation failures. Leave adequate space around items and place narrow-neck bottles upside down. Use perforated trays or baskets to support uniform steam distribution and drainage.Conduct daily checks

Begin each working day with a visual inspection. Check the door gasket and seals for wear or contamination. Verify that probes are clean and correctly placed. Look for alert messages such as ‘Refill Water’ and ensure the locking mechanism operates smoothly.Keep the water system clean

Contaminated water can damage internal components. Regularly inspect the water reservoir for debris, microbial build-up or media residue. Clean up spills immediately to prevent blockages in valves, pipes or drainage systems.Perform weekly autoclave maintenance

Set aside time each week for routine care. Clean the chamber interior and temperature sensors. Inspect and clean the water level probe. Compare pressure and temperature data against a standard steam table and download cycle logs via USB. Flag and report anomalies.Test safety interlocks and features

Autoclaves are fitted with safety interlocks and a pressure relief valve to prevent hazardous operation. These systems must be tested routinely by a qualified engineer in accordance with UK HSE PM73 guidance. Clearly display testing instructions near the unit.Check autoclave accessories and perform steam generator blowdowns

Make sure any connected data printer has paper and is functioning correctly. If the unit includes a steam generator, carry out regular blowdowns to remove accumulated impurities and prevent mineral build-up.

Support from Astell

These tips have been provided by the Astell Autoclave Services Team. Astell provides installation, validation, calibration and preventative maintenance services for Astell autoclaves across the UK, alongside remote support for international users. With decades of experience in steam sterilisation, Astell helps laboratories meet compliance standards and minimise downtime through expert servicing and responsive technical support.

By following these ten autoclave maintenance tips, laboratory technicians in 2025 can improve sterilisation reliability, reduce safety risks and extend the working life of their equipment. Regular care and documentation not only support compliance with laboratory safety standards but also improve operational efficiency. And finally, take advantage of digital tools to streamline your maintenance routine. Modern autoclaves can often be integrated with lab management systems to allow for automated logs, maintenance reminders and real-time error reporting.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh