Microscopy & microtechniques

Report on Temperature Controlled Stage use for Polymer Research

Oct 03 2013

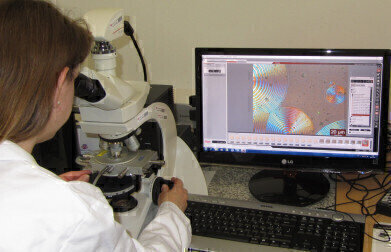

Linkam Scientific Instruments report on the use of their popular THMS600 stage for polymer research at the University of A Coruña (A UDC), Spain.

Dr Birgit Bittmann and her team at the University are using the Linkam THMS600 stage to help understand polymer materials. She explained: "The temperature stage is applied for investigations on the crystallisation behaviour of thermoplastic polymers. The crystal structure of plastics is related to their properties (e.g. mechanical properties) and, therefore, also correlates to their suitability for a range of applications. The aim of our research is to understand the relationship between processing, structure and properties of plastic materials."

The THMS600 is used in many applications where high heating/freezing rates and 0.1°C accuracy and stability are needed. Samples can be quickly characterised by heating to within a few degrees of the required temperature at a rate of up to 150°C/min with no overshoot, then slowed down to a few tenths of a degrees per minute to closely examine sample changes. The entire experiment can be saved as an online plot or exported to a spreadsheet application. There are various version options for this stage, including pressure, vacuum, electrical sample measurement and sample holders to mount the stage vertically in IR or x-ray spectrometers.

Dr Bittmann added: "The Linkam temperature stage allows us to perform a controlled heating experiment, and subsequently, to perform controlled cooling for observing the crystal growth of semi-crystalline thermoplastic polymers by means of polarised optical light microscopy. Before the Linkam temperature stage was installed in our lab, we melted the samples by putting them into an oven. We then observed crystallisation cooling down to room temperature. However, neither heating nor cooling was controlled and it was impossible to determine at which temperature crystallisation started. The temperature stage makes controlled heating and cooling possible and enables us to correlate the temperature and cooling rate to the crystallite growth in our polymers. Thus, for a determined cooling rate, we are able to determine the start of crystallisation."

Finally, she noted that the "major benefits of the Linkam THMS600 are that it is easy to use and it's accurate temperature control."

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh

.jpg)

-(2).jpg)