-

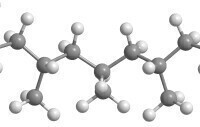

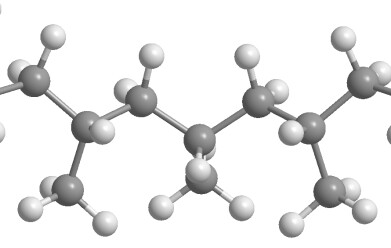

The new method accurately captured the structural changes of commonly used plastic Polypropylene during the moulding process into the end product. (Credit: PakpongICCH444/Wikimediacommons)

The new method accurately captured the structural changes of commonly used plastic Polypropylene during the moulding process into the end product. (Credit: PakpongICCH444/Wikimediacommons) -

Machine learning predicts the material properties of new polymers with high accuracy, providing a nondestructive alternative to conventional polymer testing methods. (Credit: Mike MacKenzie via Flickr/Wikimediacommons)

Machine learning predicts the material properties of new polymers with high accuracy, providing a nondestructive alternative to conventional polymer testing methods. (Credit: Mike MacKenzie via Flickr/Wikimediacommons)

Research news

Predicting polymer mechanical properties with machine learning

Sep 09 2024

A new study demonstrates how a machine learning algorithm can predict the behaviour of new polymer materials using X-ray diffraction data.

Polymers, such as polypropylene, are integral to modern life, used in products ranging from cars to electronics. Because of their widespread use, understanding how new polymers will perform under various conditions is crucial. A recent study, published in Science and Technology of Advanced Materials, shows that scientists can now leverage machine learning to anticipate the behaviour of newly developed polymers.

Traditionally, predicting the mechanical properties of polymers, including tensile strength and flexibility, requires destructive and expensive physical testing. However, a team of researchers from Japan, led by Dr Ryo Tamura, Dr Kenji Nagata, and Dr Takashi Nakanishi of the National Institute for Materials Science in Tsukuba, has developed a non-destructive method. They demonstrated that machine learning, using X-ray diffraction data, can predict the properties of homo-polypropylenes, a specific group of polymers. This method offers detailed insights into the complex structures of these materials based on their preparation conditions.

“Machine learning can use data from existing materials to predict unknown materials’ properties,” explain Drs. Tamura, Nagata, and Nakanishi. However, they emphasise that accurate predictions depend on selecting the right descriptors to represent the materials' key features.

Polypropylene, a thermoplastic crystalline polymer, has a complex structure that changes during the moulding process. This complexity makes it critical for the research team to capture accurate structural details through X-ray diffraction. They then ensured the machine learning algorithm could identify and utilise the most important features, or descriptors, from this data.

The researchers applied a tool called Bayesian spectral deconvolution to analyse two datasets. The first contained X-ray diffraction data from 15 types of homo-polypropylenes subjected to varying temperatures. The second dataset was drawn from four types of homo-polypropylenes that had undergone injection moulding. The mechanical properties analysed included stiffness, elasticity, deformation temperature, and how much the material could stretch before breaking.

The results showed that the machine learning model successfully linked X-ray diffraction features to specific mechanical properties of the polymers. Some properties, such as stiffness, were easier to predict, while others, like stretching before breakage, proved more challenging.

“We believe our study, which outlines a procedure for creating an accurate machine learning prediction model using only X-ray diffraction data, offers a non-destructive alternative to conventional polymer testing methods,” the NIMS researchers note.

Additionally, the team suggests their Bayesian spectral deconvolution approach could be applied to other techniques, such as X-ray photoelectron spectroscopy, and may help in analysing a wide range of materials, both organic and inorganic.

“This could serve as a model for future data-driven approaches to polymer design and materials science,” the researchers conclude.

More information online

Digital Edition

Lab Asia 32.2 April

April 2025

Chromatography Articles - Effects of small deviations in flow rate on GPC/SEC results Mass Spectrometry & Spectroscopy Articles - Waiting for the present to catch up to the future: A bette...

View all digital editions

Events

Apr 09 2025 Tokyo, Japan

Apr 22 2025 Hammamet, Tunisia

Apr 22 2025 Kintex, South Korea

Analytica Anacon India & IndiaLabExpo

Apr 23 2025 Mumbai, India

Apr 23 2025 Moscow, Russia