Temperature control and sterilising

Advancing sustainable temperature control with natural refrigerants

Mar 13 2025

Lauda Dr R. Wobser GmbH & Co continues to set new benchmarks in sustainable and innovative temperature control technology with the launch of the Integral IN 2040 XTW process thermostat. As the first Lauda process thermostat to utilise CO₂ as a natural refrigerant, this development marks a significant milestone, reinforcing the company’s commitment to environmental responsibility and future-ready solutions. This advancement expands Lauda’s portfolio of precise temperature control systems, incorporating eco-friendly refrigerants like carbon dioxide and hydrocarbons as alternatives to conventional F-gases.

Focus on sustainability

Approximately 95% of the CO₂ emissions generated over the lifespan of constant temperature equipment come from ongoing operation. To address this, Lauda prioritises energy efficiency and reduced CO₂ emissions by integrating electronic cooling controls, speed-controlled compressors, and natural refrigerants.

Transition to natural refrigerants

In response to the European F-Gas Regulation and advancements in refrigeration technology, Lauda has been progressively transitioning its devices and industrial systems to natural refrigerants. Depending on application requirements, location, and target temperature, Lauda offers solutions featuring carbon dioxide (R744), propane (R290), and ethane (R170).

“The switch to sustainable refrigerants not only ensures compliance with regulatory standards but also underscores our dedication to environmentally friendly temperature control technology,” said Dr Marc Stricker, Managing Director of Lauda.

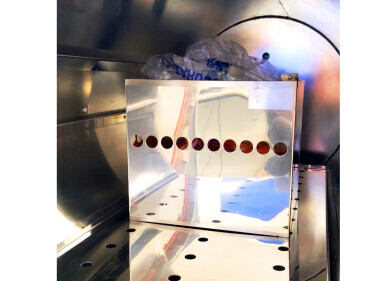

The Integral IN 2040 XTW: Innovation in process thermostats

The Integral XT series operates using a cold oil blanket and dynamic temperature control, making it ideal for precise applications across a broad temperature range. The Integral IN 2040 XTW introduces CO₂ as a refrigerant, offering stable cooling below 20°C, non-flammability, and a global warming potential (GWP) of just 1 - significantly lower than traditional F-gases.

With an impressive -45 to 200°C temperature range and 20.8 kW cooling output at 20°C, this advanced model combines Lauda’s proven technology with next-generation cooling efficiency. A frequency-controlled compressor enhances energy efficiency, reducing consumption by up to 50% compared to F-gas models, while also lowering noise levels for improved workplace comfort.

Additionally, the Integral IN 2040 XTW is retrofittable with interface modules for flexible process control integration and can be managed via internal LAN on a PC or tablet. This breakthrough in temperature control technology exemplifies Lauda’s commitment to innovation, efficiency, and sustainability.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh