Solutions in Science 2025

SinS 2025: The flavour chemistry of cheddar cheese explored from pasture to plate

Jul 18 2025

At the Solutions in Science 2025 conference in Brighton, United Kingdom, Professor Kieran Kilcawley, Principal Research Officer at the Teagasc Food Research Centre, Cork, in the Republic of Ireland, delivered a keynote lecture on the intricate flavour chemistry of cheddar cheese. Drawing on more than two decades of research, he offered a comprehensive overview of the biochemical, environmental and analytical processes that shape cheddar’s flavour, with particular attention to volatile organic compounds, starter cultures and advanced chromatographic techniques.

Ireland exports approximately €270 million worth of cheddar cheese to the UK alone each year, with additional markets continuing to emerge. A key differentiator in Irish cheddar production is the country’s grass-based milk supply. About 90% of Ireland’s dairy cows graze on pasture year-round – an uncommon feature even among grass-based systems elsewhere. This results in milk enriched in omega-3 fatty acids and conjugated linoleic acids, which are ultimately expressed in the cheese.

Teagasc, the Irish Agriculture and Food Development Authority, operates with approximately 1,300 staff and an annual budget of €200 million. Although it does not confer academic degrees, the organisation is highly ranked in agricultural and food sciences within Ireland and collaborates closely with institutions such as University College Cork and the Technical University of Dublin. Professor Kilcawley’s research is based at its Moorepark facility in Cork that integrates farmland, dairy herds and food processing infrastructure into a unified farm-to-fork model. The Flavour Chemistry Facility, which was established in 2018, supports both fundamental and commercial research on volatile organic compounds and fatty acid profiles.

Kilcawley explained that milk quality, especially the protein-to-fat ratio, must be standardised to ensure product consistency of the cheese. Seasonal changes in cow lactation require adjustments, while the process of pasteurisation eliminates both beneficial as well as undesirable microbes. In this context, the selection of a suitable starter culture becomes essential to flavour development of the cheddar.

He outlined several key stages in the cheese production process that influence flavour formation:

- The introduction of the starter cultures is the most critical step, as it bring microorganisms to initiate fermentation and drive enzymatic synthesis of flavour compounds.

- The curdling and cutting process, involving rennet and acidification, alters the biochemical environment of the curd.

- Maturation – typically lasting from three to 12 months – facilitates enzymatic breakdown of fats and proteins into aroma- and flavour-contributing compounds.

While diet and milk composition initially affect flavour, these factors are ultimately overshadowed by microbial metabolism during ripening. The mature flavour profile of cheddar cheese is thus primarily determined by enzymatic activity from starter and adjunct cultures.

Flavour in cheddar cheese arises from three principal biochemical routes:

- Proteolysis, the breakdown of milk proteins into peptides and amino acids, is the most influential pathway. Microbial metabolism of these compounds yields a wide array of volatile organic compounds, including sulphur compounds, acids, aldehydes and alcohols.

- Lipolysis, though slower, contributes short-chain fatty acids and ketones that can enhance or impair flavour depending on concentration.

- Glycolysis is largely restricted to early ripening when residual lactose is present. However, within two weeks of the start of the maturation process, lactose levels typically fall to below 1%.

Flavour perception occurs retronasally – through the mouth and into the sinus from the back of the mouth – as volatile compounds travel to the olfactory epithelium during consumption. Professor Kilcawley cautioned that compound abundance alone does not predict sensory relevance. Instead, odour activity values – the ratio of compound concentration to its odour threshold – offer a more informative metric.

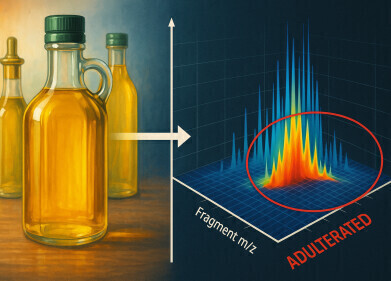

Teagasc’s researchers use a suite of analytical tools to study volatile organic compounds:

- Gas chromatography and comprehensive two-dimensional gas chromatography separate complex mixtures.

- Solid phase microextraction and HiSorb™ extraction concentrate analytes prior to analysis.

- Gas chromatography-olfactometry incorporates trained assessors to identify aroma-active regions within chromatograms.

Although descriptive sensory analysis is performed, it is resource-intensive and reserved for high-priority projects.

No single extraction technique captures the full volatile profile of cheese. Instead, different methods introduce distinct chemical biases with the agency’s work producing comparative studies of:

- Headspace HiSorb™, ideal for capturing highly volatile compounds.

- Direct immersion HiSorb™, better suited to semi-volatile and non-volatile analytes.

- Traditional solid phase microextraction, used as a benchmark but increasingly supplanted due to limitations in reproducibility.

The extraction method must be selected based on the analytical objective, especially for untargeted profiling. Acidic compounds, for example, are best extracted using specific polar phases. The Teagasc team has constructed an in-house spectral library validated with authentic standards to improve identification reliability.

Cheddar cheese presents a formidable challenge for volatile compound analysis in that it contains water, fat, protein and salt, all of which interfere with volatilisation. This makes sample preparation critical. For example, freezing alters the volatile profile and is to be generally avoided, while extraction temperatures need to be kept below 40°C in order to prevent thermal artefacts – melted cheese. Partitioning behaviour also influences compound retention, with the oil–water partition coefficient and compound polarity informing sorbent selection and analytical conditions.

To support sensory interpretation, the team developed a cheddar aroma wheel with around 50 key compounds categorised as:

- Green/fatty – aliphatic aldehydes and alcohols.

- Rancid – short-chain fatty acids.

- Cheesy – sulphur compounds and methional.

- Buttery – diacetyl and diketones.

- Earthy/malty – pyrazines and furans.

- Fruity – esters and aldehydes.

- Creamy/sweet – lactones and sugar derivatives.

Buttery notes dominate younger cheeses, while more complex aroma notes – particularly those from amino acid catabolism – emerge later in the ripening period. A rise in fruity compounds during maturation can signal microbial imbalance or early spoilage and can suggest that this batch requires early processing for sale.

Recent studies using milk from cows fed on grass compared to a concentrate feed have shown striking aroma differences. Grass-fed cows produce cheese with fresh, grassy notes, while concentrate-fed milk results in heavier, more ‘processed’ aromas. Even minor compounds from forage – such as terpenes and pyrrolidines – can persist through processing and contribute to the cheese’s sensory profile. These findings offer opportunities for product traceability and ‘terroir-based’ differentiation.

“Cheddar cheese flavour is shaped by a complex interplay of microbial, biochemical, environmental and other analytical factors,” said Professor Kilcawley.

“The starter culture exerts a particularly powerful influence on the development of flavour compounds during maturation.”

He concluded by noting that, although cheddar is one of the most studied cheeses, much of the foundational research is now more than two decades old. Novel analytical approaches and rigorous sensory science now offers significant opportunities to enhance quality assurance and drive innovation.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh