Solutions in Science 2025

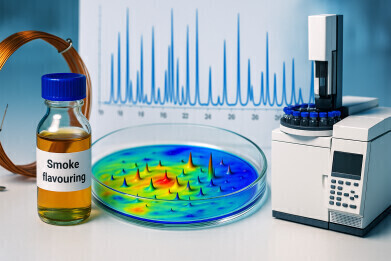

SinS 2025: Smoke flavourings EU ban prompts closer analysis using advanced gas chromatography

Jul 18 2025

“Flavourists need to understand the compositional differences between smoke flavourings if we are to maintain product quality under tightening regulatory constraints,” said James Grufferty, an analytical chemist at Sensient Flavours, during his presentation at the Solutions in Science 2025 conference in Brighton, United Kingdom. His presentation explored the application of comprehensive gas chromatography to characterise primary smoke flavourings – identify genotoxic risks – and inform possible reformulation strategies.

Gafferty began by describing the context of smoke flavouring in food science. Sensient Flavours, a multinational company headquartered in the United States, specialises in colours, flavours and botanical extracts which are used across the food and beverage industry. Smoke has long been used to preserve and flavour food, with its origins traceable over many thousands of years to the earliest human practices.

Modern smoke flavourings are produced through the pyrolysis of wood at temperatures below 600°C to avoid the formation of the most toxic by-products. The resulting condensates are typically fractionated to isolate desirable flavour compounds and for the removal of tar which, itself, contains potentially harmful polycyclic aromatic hydrocarbons.

Historically, there have been ten primary smoke flavourings made available commercially within Europe, each assigned a unique substance number. These are used in products such as snacks, sauces and ready meals. However, Gafferty explained that recent regulatory changes have begun to restrict their use. By late 2023, the European Food Safety Authority – an agency of the European Union – concluded that eight out of the list of ten smoke flavourings posed genotoxic risks, not because of polycyclic aromatic hydrocarbons but due to specific compounds including catechol and 2-methoxyhydroquinone. In vivo mice studies showed some genotoxicity resulting from exposure to these compounds.

Manufacturers of SF-10, the remaining smoke flavour under review, chose not to provide the additional toxicological data required to retain its authorisation. As a result, all of these primary smoke flavourings are now in the process of being phased out. Existing stocks may continue to be used until 2029 – in existing product lines – but no use is permitted for new product development. Gafferty noted that this development poses significant difficulties for industry stakeholders that rely on the use of these flavourings.

To support reformulation efforts, Gafferty and his team at Sensient conducted a detailed compositional analysis of six affected primary smoke flavourings – SF-1, SF-2, SF-4, SF-5, SF-6, and SF-8 – all of which were supplied by third-party manufacturers. Initial investigations were carried out using one-dimensional gas chromatography with headspace solid phase microextraction. Direct injection was ruled out due to the viscosity and complexity of the samples, which could damage analytical columns.

Even with one-dimensional gas chromatography, the samples were found to be chemically rich and varied, containing phenolics, acids, alcohols and other volatile components. Gafferty highlighted the analytical challenge posed by numerous small peaks in the chromatograms, each contributing subtly to the overall flavour profile. Recognising the limitations of one-dimensional separation, he sought to apply a more sophisticated approach.

Gafferty detailed how Sensient partnered with the Open University to gain access to comprehensive two-dimensional gas chromatography facilities. The collaboration, made easier by geographical proximity of the firm and the university’s lab, enabled the analysis of the same six smoke flavourings using its LECO BT Series instrument. Samples were again prepared using headspace solid-phase microextraction, although the volume had to be reduced significantly in the case of SF-4 due to the sample’s particularly high concentration.

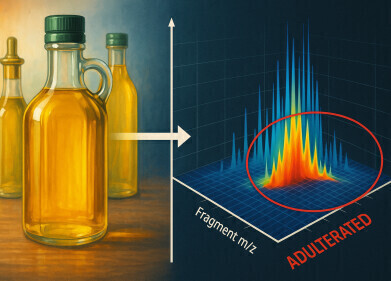

The use of two-dimensional gas chromatography revealed far greater chemical detail than had been observed in the one-dimensional analyses. The contour and surface plots demonstrated a clearer separation of a wider array of structurally related compounds. Among them were catechol, 2-methoxyhydroquinone and 4-propoxy-catechol – all of which have been identified as genotoxic.

Gafferty noted that each smoke flavouring displayed a unique chromatographic signature, consistent with differences in aroma and taste observed by sensory analysts. To move beyond visual interpretation, he applied chemometric tools within the LECO’s ChromaTOF software suite. These included the Tile feature for automated compound tracking and principal component analysis to explore statistical variance across samples.

Principal component analysis was conducted on five replicates for each of the six smoke flavourings, generating 30 analytical profiles. The distinct chemical profile of SF-4 was shown to a clear outlier compared next to the other smoke flavours. The remaining samples clustered in distinct groups, with SF-1 and SF-5 showing the greatest separation – reflecting their underlying compositional differences.

Further analysis revealed which compounds were more abundant in specific flavourings. SF-4 contained higher levels of cresol and 4-methylguaiacol, compounds known to impart intense smoky or medicinal notes. In contrast, SF-5 exhibited elevated levels of ketones such as 2-nonanone and furfural derivatives, which contributed aromas of a fruity or caramel character.

Gafferty emphasised that this type of profiling provides valuable information for formulation scientists aiming to replicate the sensory impact of these regulated (and soon to be banned) substances. By pinpointing key volatile markers, developers can design replacements that mimic the flavour profile of phased-out products with greater precision and increased safety.

In a related study, the team investigated the effect of sample preparation on analytical sensitivity. In routine practice, Sensient analysts often dilute samples in salt solution to facilitate extraction. Gafferty compared this approach with the use of undiluted (neat) samples. The neat samples yielded significantly richer chromatographic profiles, suggesting that certain compounds may be lost or masked during salt-based preparation.

He proposed a follow-up study using principal component analysis to compare the two approaches and identify any compounds that were upregulated or downregulated by the salt (or other) sample preparation method. This work, he suggested, could help improve the accuracy and reproducibility of future analyses.

The EU regulatory decision to restrict primary smoke flavourings has left manufacturers searching for alternative solutions. The use of comprehensive gas chromatography and chemometric tools has allowed Sensient to characterise flavour profiles at high resolution and begin to guide the development of acceptable substitutes.

Gafferty acknowledged that further work is required to understand how pyrolysis conditions and the choice of hardwoods influence the final composition of smoke flavourings. Manufacturers rarely disclose such formulation details, making reverse engineering difficult. However, by continuing to analyse these systems, researchers may eventually uncover consistent links between raw materials, processing conditions, and chemical output.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh