-

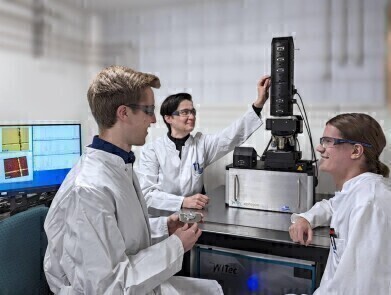

Florian Klein (left) and Leon Gläser (right) from the ZSW in Ulm together with WITec Application Scientist Dr. Ievgeniia Iermak (middle) during training on the new Raman microscope.

Florian Klein (left) and Leon Gläser (right) from the ZSW in Ulm together with WITec Application Scientist Dr. Ievgeniia Iermak (middle) during training on the new Raman microscope.

News

Raman Technology to assess Electrode Performance

Mar 28 2023

The Center for Solar Energy and Hydrogen Research (ZSW) Baden-Württemberg has installed a Raman microscope for use in its new pilot plant in Ulm, where cathode materials for lithium-ion batteries will be produced and the scalability of fabrication methods will be investigated.

The performance of Lithium-ion batteries, a primary enabling technology in the current shift toward electric mobility, is almost exclusively determined by the materials used. Over the next 12 months ZSW is constructing the Powder-Up pilot plant that will focus on making improvements in the next generation of battery electrode materials and on scale-up of manufacturing processes. This work is set to have far-reaching effects in terms of battery performance, resource use and unit costs.

According to Dr. Margret Wohlfahrt-Mehrens, head of the Accumulators Materials Research department, “Raman microscopy is becoming a standard method in applied battery research. It quickly provides detailed information about how different electrode formulations function and degrade over charge cycles.”

WITec GmbH won the Europe-wide public tender due to the chemical sensitivity, spatial resolution and acquisition speed of its Raman imaging systems.

In a reflection of Baden-Württemberg’s innovative strength, WITec’s headquarters and ZSW’s facilities are located on the same hill above Ulm. “It really highlights that this region is central in Germany’s efforts to support the green revolution,” said Harald Fischer, Marketing Director at WITec.

“We designed and built this microscope right here and then delivered it across our neighbourhood, where it will further the development of one of today’s most crucially important technologies.”

The Powder Up facility, funded by the Baden-Württemberg Ministry of Economic Affairs, Labour and Tourism and the German Federal Ministry of Education and Research (BMBF), is the first of its kind in Europe. Material batches of up to 100 kilograms can be produced in the new plant. Such quantities are required to produce large battery cells for electric cars or stationary energy storage units.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh