-

FlowSyn continuous flow reactor system. (courtesy : Uniqsis)

FlowSyn continuous flow reactor system. (courtesy : Uniqsis) -

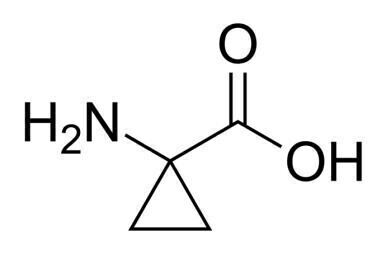

Example of a chiral Cyclopropane carboxylic acid.

Example of a chiral Cyclopropane carboxylic acid.

Laboratory products

Scalable flow method produces enantiomerically pure pharmaceutical intermediates

Mar 20 2024

Researchers at Lilly SA have pioneered a ground-breaking continuous flow method for the Wadsworth–Emmons cyclopropanation of alkyl-substituted chiral epoxides into chiral cyclopropane carboxylic acids, as reported by Uniqsis.

Utilising a custom setup comprising the FlowSyn continuous flow reactor and binary pump, the researchers successfully devised a novel flow process that overcame challenges associated with high temperature, pressure, and the volatile nature of the epoxide starting material.

The FlowSyn flow reactor demonstrated heightened efficiency by maintaining a higher concentration of low-boiling-point reactants in the liquid phase, due to its reduced headspace, resulting in enhanced reactivity compared to batch methods employing sealed vessels.

Furthermore, the researchers integrated their cyclopropane formation process with in-line workup and hydrolysis transformations, yielding enantiomerically pure cyclopropane carboxylic acids in impressive yields of up to 100 grams.

Uniqsis's FlowSyn, designed by a team of experienced flow chemists and engineers, stands as a fully integrated continuous flow reactor solution. Offering seamless reaction optimization and scale-up capabilities from milligrams to hundreds of grams, FlowSyn serves as a versatile tool for pharmaceutical intermediates production.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh