Gas chromatography

How brewers and cider makers can stay on top of ABV limits with the Ellutia 200 Series GC

Aug 06 2025

For today’s brewers and cider makers, getting alcohol by volume (ABV) right is more than a quality issue, it’s a legal requirement and a matter of consumer trust. Whether you’re producing a traditional ale, a crisp cider, or a non-alcoholic beer or cider, accurate testing is what ensures that what’s on the label is exactly what’s in the glass.

In the UK, a drink labelled “alcohol free” must contain no more than 0.05% ABV. In the United States and much of Europe, the limit is 0.5%. For non-alcoholic beer and cider, even a fraction of a percent over can mean fines, product recalls, or losing vital retail contracts. With demand for alcohol-free products increasing year on year, the scrutiny on producers has never been higher.

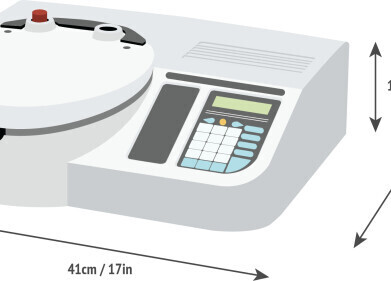

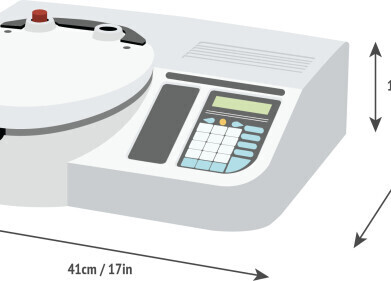

That is why many breweries and cideries are choosing the Ellutia 200 Series Gas Chromatograph. Compact, user friendly, and designed for real world production environments, the 200 Series GC with Flame Ionisation Detection (FID) delivers ethanol measurements with precision down to 0.01% ABV. For producers, that means knowing with confidence that their non-alcoholic beer and cider products meet regulatory standards, and keeping their promises to customers.

The benefits of bringing ABV testing in house go far beyond compliance. Producers can:

- Confirm fermentation is progressing as expected

- Verify alcohol free and non-alcoholic beer or cider claims before packaging

- Catch off target batches early, avoiding costly relabelling

- Maintain flavour consistency and shelf stability across every release

A leading global brewer recently adopted the 200 Series GC to protect its alcohol-free and non-alcoholic range. By running quick, routine checks on site, they confirmed every batch remained below 0.05% ABV, even at scale. The result was faster decision making, fewer risks of regulatory setbacks, and stronger trust from retail partners and consumers alike.

With straightforward workflows and minimal sample preparation, the 200 Series GC integrates seamlessly into production routines. From mid fermentation checks to final bottling validation, it gives brewers and cider makers the data they need to keep non-alcoholic beer and cider consistent, compliant, and ready for market.

As the low and no alcohol sector continues to grow, investing in accurate, in house ethanol testing is not just good practice, it’s essential.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh