Autoclaves

Low pressure (up to 2.4 Bar) laboratory steam autoclaves

Jul 07 2010

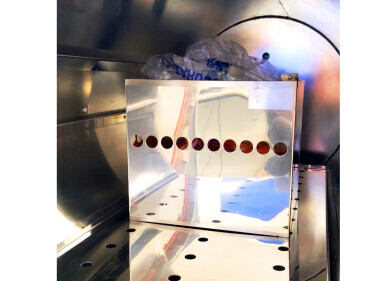

Since its foundation in 1988, Priorclave have grown to become one of the UK’s premier manufacturers of low pressure (up to 2.4 Bar) laboratory steam autoclaves for use in laboratories throughout the food, drink, dairy, health and pharmaceutical industries.

Priorclave’s range extends from smaller, bench top models to larger, floor standing, top and front loading versions in circular and rectangular formats with loading capacities from 40L – 700L and above.

For the smaller laboratory with a requirement for autoclaving in-house on a tight budgets The OPAL entry-level range has been introduced to perform media preparation and waste sterilising, without unnecessary expenditure on additional functions and control systems often fitted as standard on many of today’s autoclaves.

Priorclave’s autoclaves are manufactured using modern CNC equipment, allowing quick response to customers’ demands for high quality, cost-effective, infection control and sterilisation equipment. With an in-house design team and more than 2,500 M2 manufacturing facility Priorclave are able to offer bespoke designs to suit particular applications when required.

As an approved manufacturer of pressure vessels and systems for autoclaves, manufacturing processes and designs are carefully scrutinised by Zurich Insurance under the European Pressure Vessel Directive –97/23/EC in addition to a BS EN ISO9001:2008 Quality System.

Priorclave innovate and have turned innovation into de facto standards. Low loading heights, compact designs, modular construction for easy upgrading, thermal safety lock on all models, TACTROL® full microprocessor control across the whole range, media warming, vacuum assisted cooling, application led literature are now commonplace features that were introduced by Priorclave to the UK autoclave market.

The latest innovation is their collaboration with BioCote® to produce the first range of laboratory autoclaves that have the capacity to inhibit the growth of bacteria outside as well as inside the autoclave. BioCote®‘s unique powder coating is applied to all models across the range to boost standards of laboratory hygiene and is effective throughout the lifetime of the equipment.

To continue to provide the best for their customers Priorclave are fully committed to:

- Continued operation of an ISO9001:2008 Quality System.

- Full EMC Compliance Testing.

- Monitored approval of pressure vessel design and welding procedures to European and International Standards.

- Continued investment in new technology.

- Continued development of products, keeping quality- conscious laboratories at the cutting edge of technology.

- Design of equipment that is reliable, easy to operate and good value for money.

- Continued use of the best materials available e.g. pressure vessels are only made from grade 316L stainless steel for its superior corrosion resistance over other grades.

- Maintaining a dedicated Service & Technical Support Team.

- UKAS Accreditation as a Calibration Laboratory.

More details about Priorclave and their full range of autoclaves are available on their website on www.priorclave.co.uk. where clients can construct their own technical data sheet and price guide according to the type of use and application required.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh