-

Eco-friendly sterilization of GMO-contaminated wastewater is a key component of horticultural biotechnology

Eco-friendly sterilization of GMO-contaminated wastewater is a key component of horticultural biotechnology

Autoclaves

Horticultural GMO research and effective liquid waste management

Jul 15 2025

With longer and more pernicious heatwaves occurring with increasing regularity, genetic modification of food crops may become an essential component in ensuring global food security. Increased drought resistance, heat tolerance, and reduced yield losses are all part of the potential panacea that horticultural genetic modification offers.

Supporting this continually expanding field of global research is the need for easily implemented biohazard containment practices. Waste decontamination is an essential—if unglamorous—element of this process. Legislation, including the EU Directive 2009/41/EC and the UK’s Contained Use Regulations, requires that all waste at level 2 and above— including contaminated wastewater—be appropriately deactivated before it exits a facility. Compliance becomes increasingly stringent as Containment Levels (or Biosafety Levels) rise.

Handling contaminated liquids is more complex than managing solid waste due to their fluid nature. According to Genetically Modified Organism (GMO) Public Register Notifications submitted to the UK Health and Safety Executive, some horticultural research facilities have classically managed liquid waste by minimising water use and allowing it to evaporate, thereby reducing the risk of the unintentional release of contaminated wastewater, or “run-off”. This approach aligns with the general principle in EU Directive 2009/41/EC to control contaminated run-off.

However, in most modern GMO horticulture laboratories, hydroponics offers a more controllable, measurable, and space-efficient method for growing plants. This results in higher growth rates and faster life cycles, ultimately accelerating the pace of research. Unlike traditional watering methods, hydroponics places water at the core of the growing process—making it a voluminous and indispensable input. Consequently, this reintroduces the challenge of safely deactivating GMO material in the resulting wastewater.

Although hydroponic systems are typically designed to minimise wastewater through recirculation—facilitating general compliance with run-off control measures—some wastewater production is unavoidable. System resets, partial water changes, and periodic flushing can generate significant volumes of liquid waste. Integrating a sterilisation device directly into the hydroponic system simplifies this waste management process and significantly reduces the likelihood of run-off. Wastewater can be plumbed from the hydroponic system into the sterilisation unit via an unbroken pathway, maintaining full containment.

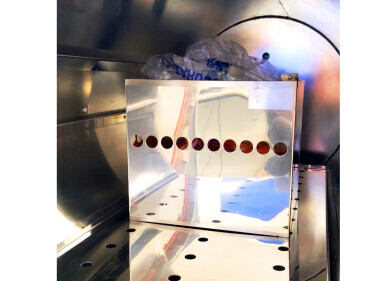

Autoclaving remains a highly effective and deeply penetrative method of sterilisation, easily validated using thermal, pressure, and biological indicators. It is also environmentally friendly, relying solely on electricity and water to function—making it as sustainable as the lab’s energy supply. However, traditional autoclave processes require fluids to be transferred manually into containers, which are then loaded into the chamber for sterilisation. This introduces potential for spillage and accidental run-off.

The AstellBio liquid waste autoclaves offer an ideal solution: they automatically collect wastewater directly from hydroponic systems, sterilise it using the autoclave process, and dispose of it without any manual intervention. This fully automated process eliminates the risks associated with manual handling and removes the need for chemical sterilants. With a range of devices capable of sterilising anywhere from tens to thousands of litres of GMO-contaminated liquid waste per day, AstellBio provides liquid waste autoclaves and effluent decontamination systems that support horticultural research globally.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh