-

Credit UCL

Credit UCL

News

Low Light Activated Coating Beats Bacteria

Mar 17 2020

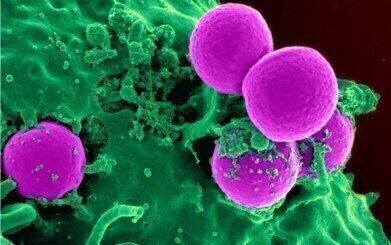

Researchers at University College London (UCL) have developed the first light activated antimicrobial coating that has been successful in killing bacteria at low light intensity.

Offering potential for use on phone screens and keyboards, it was found effective against health-care associated infections (HCAIs) such as Clostridioides difficile (C. difficile), methicilli-resistant Staphylococcus aureus (MRSA) and Escherichia coli (E. coli), that commonly occur during in-patient medical or surgical treatment, or from visiting a healthcare setting.

The new bactericidal coating, made of tiny clusters of chemically modified gold embedded in a polymer with crystal violet – a dye with antibacterial and antifungal properties- was the first such coating to show success (1) at killing these bacteria at low intensity, ambient light (300 lux) common in wards and waiting rooms. Similar coatings have needed intense light (3,000 lux), such as found in operating theatres to activate their killing properties.

First author, Dr Gi Byoung Hwang (UCL Chemistry), said: “Dyes such as crystal violet are promising candidates for killing bacteria and keeping surfaces sterile as they are widely used to disinfect wounds. When exposed to bright light, they create reactive oxygen species, which in turn kill bacteria by damaging their protective membranes and DNA. This is amplified when they are paired with metals such as silver, gold and zinc oxide.”

“Other coatings have effectively killed bacteria but only after exposure to UV light, which is dangerous to humans, or very intense light sources, which aren’t very practical. We are surprised to see just how effective our coating is in killing both S. aureus and E. coli in ambient light, making it promising for use in a variety of healthcare environments,” added Professor Ivan Parkin (UCL Chemistry), senior author and Dean of UCL Mathematical & Physical Sciences.

The team unexpectedly discovered that the coating kills bacteria by producing hydrogen peroxide – a relatively mild reagent used in contact lens cleaner solutions. It works by chemically attacking the cell membrane, and therefore takes longer to work on bacteria with more layers of protection.

“The gold clusters in our coating are key to generating the hydrogen peroxide, through the action of light and humidity. Given the clusters contain only 25 atoms of gold, very little of this precious metal is required compared to similar coatings, making our coating attractive for wider use,” commented senior author Professor Asterios Gavriilidis (UCL Chemical Engineering).

The research was funded by the Engineering and Physical Sciences Research Council, through the Advanced Flow Technology for Healthcare Materials Manufacturing (MAFuMa) project.

Visit www.ucl.ac.uk for further information

(1) Published in Nature Communications

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh