Laboratory products

New vacuum pump VACUU·PURE® 10C

Nov 03 2020

With the new VACUU·PURE® 10C, VACUUBRAND introduces a unique chemically resistant, oil-free screw pump for vacuum down to 10-3 mbar. The pump features maintenance-free technology with no wear parts and delivers a pumping speed of 9 m3/h.

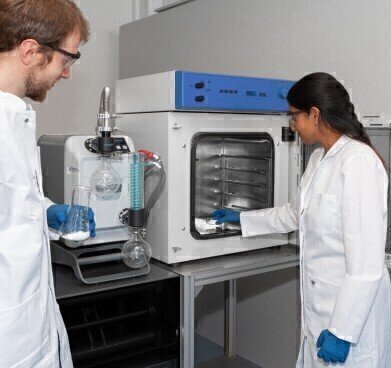

VACUU·PURE 10C is the ideal solution for processes in which aggressive gases or vapors are pumped and clean vacuum is also required. This lets the vacuum pump cover many application areas in the fields of analytics, chemistry, life sciences, pharmaceuticals, for work ranging from bench-scale research & development up to the kilo laboratory. It is ideal for processes such as vacuum drying, Schlenk lines, heat treatment, distillation, degassing, coating, or as fore vacuum for turbomolecular pumps. VACUU-PURE is a new, innovative technology for the vacuum range down to 10-3 mbar. Uniquely among fine vacuum pumps, VACUU∙PURE pumps can also be used continuously at higher pressures, i.e. in the complete working range between atmospheric pressure and the ultimate vacuum of the pump.

Clean processes and sustainability

VACUU·PURE is a significant advancement of dry screw pump technology. VACUU∙PURE’s special design features two cantilevered spindles and a magnetic gear which is completely oil-free. The spindles run contact-free, eliminating wear and abrasion. This allows clean processes and pure products without contamination by oil or lubricants in the entire vacuum range down to 10-3 mbar. This also contributes to the protection of the laboratory and the environment, as oil emissions and waste oil disposal are eliminated. Due to the contact-free, lubricant-free design, no regular maintenance is required. The vacuum – and the purity of the process – is not affected by wear and tear of wear parts.

High chemical compatibility and efficiency

To work with aggressive gases or vapors, wetted components of the vacuum pump are all made of chemically resistant plastics. A thick PEEK encapsulation protects the spindles and stator in the pump chamber. The high chemical compatibility allows efficient pumping without interruption – an upstream cold trap is not necessary in most processes. The optimized screw pump also features high condensate tolerance, which means that no gas ballast is required, even with high chemical vapor generation. An integrated regeneration mode allows the vacuum pump to dry quickly after the end of the process.

Product variant for non-corrosive processes

For working with non-corrosive media there is the product variant VACUU·PURE® 10 without chemical compatibility. It is designed for high-purity processes where dry- and hydrocarbon- free vacuum is a must. VACUU·PURE 10 also provides dry vacuum down to 10-3 mbar. With no oil, abrasion, or wear parts, this pump is ideally suited for applications like providing fore vacuum for high or ultra-high vacuum systems, e.g. as backing pump for turbomolecular pumps.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh