Laboratory products

As the Shut the Sash campaign gathers momentum in universities on both sides of the Atlantic, Temperature Electronics Ltd (TEL) has launched an upgraded auto sash controller to help academic institutions and industrial operations to achieve their energy consumption and carbon emission targets.

The Higher Education Funding Council for England (HEFCE) has stipulated a reduction of carbon emissions across the university sector by 43% by 2020 (against a 2005 baseline). Shut the Sash aims to help academic institutions to achieve this reduction by encouraging laboratory-based students, researchers and staff to close fume cupboard hoods when the units are not in use.

In many universities and industrial operations, manual closure and therefore the mindfulness of users is required. TEL’s auto sash controllers automatically close cupboards when they detect that there is no operator present.

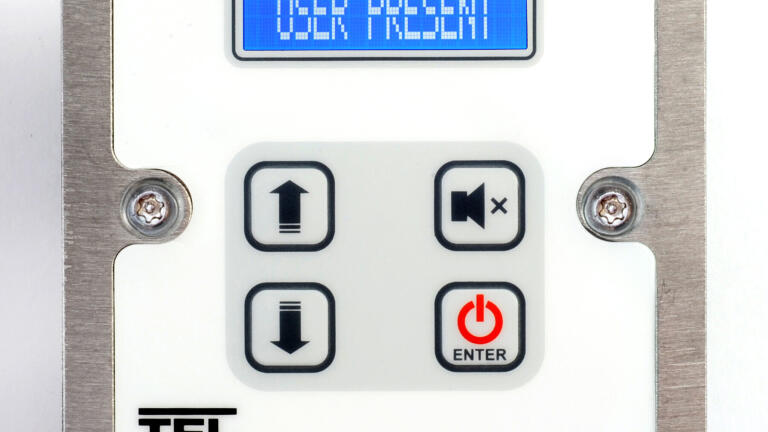

This summer, TEL has upgraded its auto sash controllers. Unlike many on the market, TEL’s products now feature a digital display, facilitating easier calibration and operation. They also incorporate a new under sash sensor in place of the original light curtain; this has resulted in a 25% reduction in price.

TEL believes that the installation of its product has the capacity to save customers previously operating without controllers approximately £1000 in energy costs per fume cupboard per year, quickly covering its own cost.

TEL’s upgraded auto sash controller has already been well-received across the globe, with the company currently undertaking a series of major commercial and university orders.

Said TEL director, Richard Eady: “Auto sash controllers present laboratory managers in academia and industry with the opportunity to make massive energy, cost and carbon emission savings.

“Our products are already well known throughout universities across the world, and we are confident that our modified auto sash controller will cost-effectively support these institutions in their Shut the Sash campaigns.”

The launch follows that earlier this year of TEL’s local exhaust ventilation (LEV) monitor. Commented Eady: “TEL is a world-leading electronic airflow control and monitor manufacturer and consultant, and our research and development team is constantly developing new products to cost-effectively enable customers to comply with health and safety legislation, delivering energy and financial savings and a reduction in carbon emissions.”