Laboratory products

Automatic mass comparators series AKM-2 and AKM-4 are RADWAG response for market demand on very reliable and accurate instruments for comparison of mass standards and weights. The AKM-4 and AKM-2 are intended for automatic determination of mass deviations in weights with operator’s activity limited to the minimum.

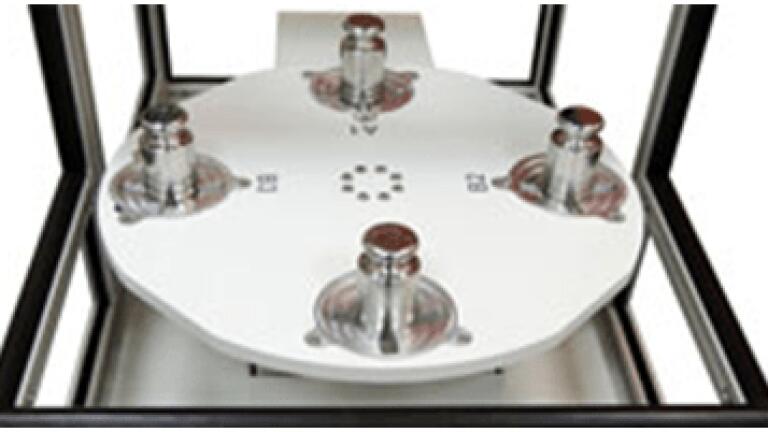

Automatic mass comparator series AKM-4

The instruments are commonly applicable in mass measuring laboratories, and particularly in certification units for weights classes E, F and M.

Design and functionality:

AKM-2

The supervising part of a mass comparator is a digital module which cooperates with a controller of instrument’s mechanical components. Automatic mass loader features a basis with self-centering fields, a robot and steel body. The digital module and the robot are located in mass comparator’s weighing chamber. The robot is controlled by the computer’s controller. The instrument is operated from level of mass indicating digital display which is plugged to mass comparator’s controller.

The supervising part of a mass comparator is a digital module which cooperates with a controller of instrument’s mechanical components. The digital module and the automatic loader are located in mass comparator’s weighing chamber. The instrument is operated from level of mass indicating digital display which is plugged to mass comparator’s controller.

The supervising elements are not integrated with mass comparator’s mechanical parts, thus enabling separation of instrument’s weighing chamber from ambient conditions influence.

Highlights:

• Comparison of weights up to 50 kg (AKM-2) or 2 kg (AKM-4);

• Fully repeatable weight loading on mass comparator's platform;

• Elimination of error caused by human factor in the process of loading weights (repeatable conditions of load placing on instrument’s platform).

Cooperation with computer:

It is possible to operate the mass comparator from PC computer level with installed dedicated software. The measurement processes carried out by the mass comparator are recorded by the supervising digital module or a plugged PC computer. The complete control process can be reported from computer level.