Laboratory products

Microlute® CP: SPE Performance You Can Count On

Sep 03 2025

Sample preparation is essential for accurate, robust and reproducible analysis. Solid phase extraction (SPE) is one of the most used sample preparation methods and offers the cleanest extracts for injection. However, the traditional loose packed form of SPE has inherent issues that can compromise the quality of sample preparation.

The Microlute® CP range of polymeric SPE products overcomes these challenges through its innovative composite technology designed to improve the consistency and reliability of chromatographic analysis.

The Issues with Loose Packed SPE

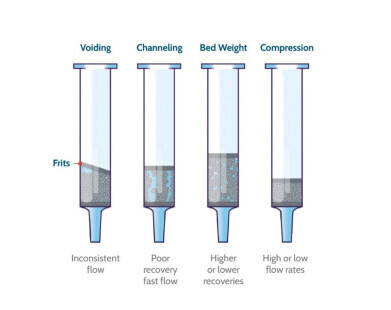

Loose packed SPE products consist of resin packed between two polyethylene frits. This results in several unavoidable issues:

- Voiding – Frits inserted at an angle, or particles settling during handling, can lead to voids within the packed bed, reducing capacity and solvent flow.

- Channelling – Solvent flow can displace particles creating preferential paths through the resin, reducing solvent contact with the rest of the sorbent.

- Bed weight inconsistency – Variation in the amount of resin packed into each plate well or SPE cartridge can alter solvent flow and capacity.

- Compression variance – Differences in packed bed density caused by inconsistent compression during manufacture can affect the rate of solvent flow through the bed.

All these variations cause variable analyte retention within the packed bed and can result in inconsistent recovery. Ultimately, this results in poor reproducibility, forcing users to repeat runs, spend time troubleshooting and incur higher costs.

The Microlute® CP Advantage

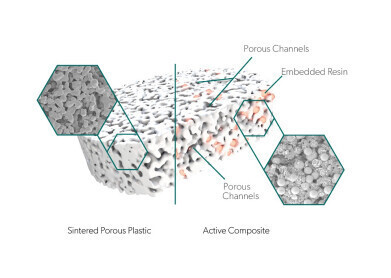

Microlute® CP provides a step change in performance, eliminating the issues present in loose packed SPE through its composite technology. Instead of following the traditional format, the chromatographically active polymeric resin is combined with inert polyethylene and sintered to form a single porous frit which is inserted into each plate well.

The key features of the Microlute® CP composite technology:

- Rigid structure - The robust, single piece design eliminates compression, allowing consistent flow rates through each well and ensuring uniform sample processing.

- Reproducible Bed Weight - Precision manufacturing controls active resin delivery, minimising variability and guaranteeing accurate and consistent bed weights across the whole 96 well plate.

- Embedded Resin - Resin is evenly distributed throughout the frit structure and secured in place. This eliminates variability and poor recovery caused by channelling and voiding.

- Consistent Liquid Flow - Enhanced flow characteristics ensure reproducibility through uniform analyte, solvent and resin interactions.

These features directly translate into greater reproducibility and increased confidence in your results. Each well delivers the same performance, so you can trust your SPE results from the first sample to the last. This minimises the need for repeat runs, cuts down troubleshooting time and reduces wasted solvents and consumables.

To find out more about the Microlute® CP range, visit our website.

For pricing or to book a demo, contact our sales team.

To see the Microlute CP in action, read the latest application note.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh