Laboratory products

The presence of excessive water in plastics adversely affects the performance of polymeric goods. This is why water determination is of crucial importance. In a technical poster, Metrohm describes the straightforward and accurate determination of the water content using the Karl Fischer Oven Method in ten different plastic types.

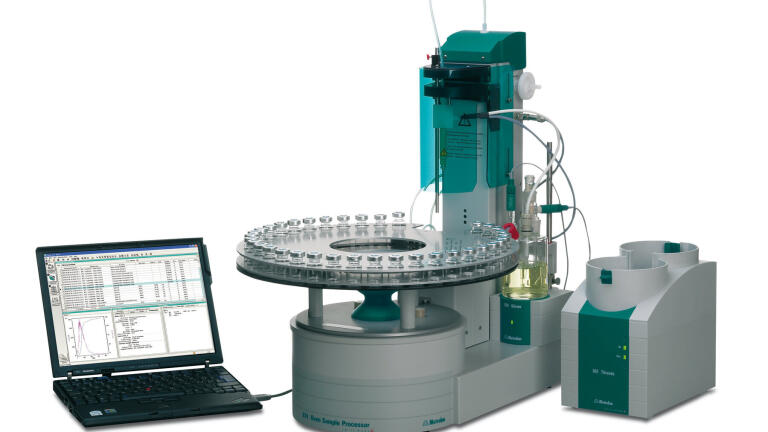

The plastic sample being tested is heated in a hermetically sealed vial. The moisture liberated from the sample is transferred via a dry carrier gas stream into the titration cell where it is coulometrically titrated. For every plastic type, the optimum oven temperature can be determined in a water release curve. This procedure ensures fast water extraction– very important – excluding interfering decomposition reactions.

Thermally stable polycarbonates, fibre-reinforced polyesters and acrylonitrile-butadiene-styrene (ABS) resins need to be heated to 230ºC to extract water. Thermally less stable resins such as polyamides and PVC need only to be heated to 150 and 100ºC, respectively.

The water content in the following plastics was determined: Terluran® GP-22 Natural; Grilamid® TR 55 Natural; Ultramid® A3K Natural; Ultramid® A3K Black; Ultramid A 3H-G5 Black; Grivory HTV-3H1 Natural; Makrolon® 1243 (colour code 550111); PET regrind (recycled); PET regrind (new); PVC.