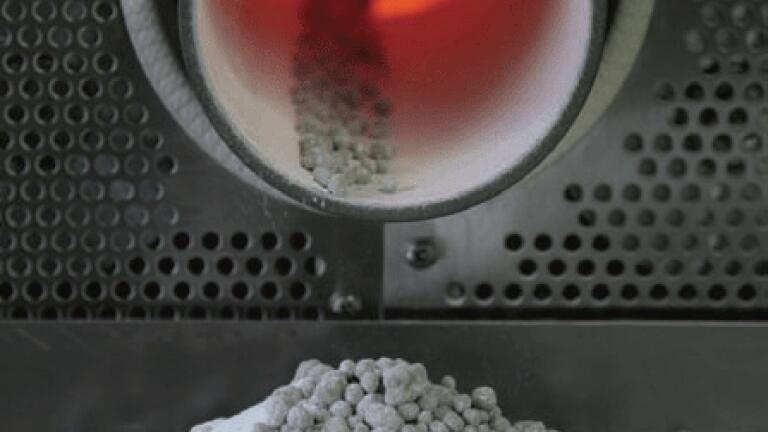

Laboratory products

Linn High Therm are offering high quality rotary tube furnaces for special heat treatments of powders and granules

with a ceramic or metallic rotary tube (inner diameter is 99mm, length is 2500mm, heated up to 1500mm).

There is an adjustable rotation speed from 0,5 up to 5rpm of the insert tube and users can adjust the inclination via the rack winch (up to 10°).

It offers 3-zone heating: fibrothal tube-heating module with embedded heating coils; Tmax 1200°C; or Kanthal Super

heating elements Tmax 1600°C.

Water cooling on the insert tube of the screw conveyor is available. Insert tubes: quartz Tmax < 1100°K, powder metalalloy < 1300°C, ceramic < 1700°C. Options include: protective gas, screw conveyor, thermal post-combustion, multideck sieves, cooling zones and vibration feeder.

Electrically heated rotary tube furnaces are used for continuous drying, oxidising of chemicals, reducing of metal

oxides, calcination and sintering of ceramic powders and granules and metal heat treatment.