Laboratory products

Improve your Containment

Jul 13 2010

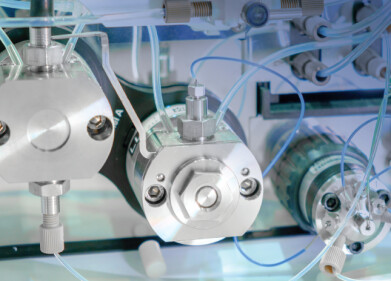

GEA Pharma Systems exhibited its Buck® containment technology at Technopharm 2010 showing its range of containment interfaces for the pharmaceutical industry. The BuckMC Valve uses only passive valves, driven

by a modular active unit. Until now it has been necessary to use one active and one passive split-valve technology to discharge product from an IBC safely. This works well when discharging to the process line however, if ingredients are to be transferred from one IBC to another, or from an IBC to a double cone dryer for example, it has always been necessary to use an active-to-active unit in between as an interface.

This is no longer necessary with the modular Buck MC Valve active unit. The Buck MC Valve is a simple method of transferring bulk active ingredients and chemicals that eliminates the need for a vacuum between the discs. It has very few moving parts, needs no lubrication and the product-touching parts can be released quickly by hand with a simple tool. Reducing the number of moving parts and standardising the components has allowed Buck to reduce the cost of the Buck MC Valve compared with competitive products.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh