Laboratory products

Safeguarding Process Integrity in the UK Pharmaceutical and Laboratory Environment

Nov 20 2025

If an operator has ever dealt with sluggish flow in a transfer line, solidified product in a tank, or inconsistent batch temperatures, they’ll know how frustrating and costly temperature-control issues can be.

At Axair Refrigeration, the team sees these challenges every day in UK pharmaceutical and laboratory environments. Whether on the lab bench or on the production floor, keeping pipelines and tanks at the right temperature isn’t just about efficiency — it’s about protecting product quality, equipment, and the bottom line.

Whether working with viscous pharmaceutical ingredients, delicate reagents, or industrial fluids, good temperature control keeps everything moving smoothly and predictably.

Why Temperature Control Matters

When process fluids drop below their ideal temperature, things can go wrong fast. Viscosity increases, pumps work harder, and before long there’s a blocked line or an unusable batch. In pharma environments, temperature-sensitive APIs can crystallise if a line cools just a few degrees too much, turning valuable material into waste.

On the other extreme, overheating can damage delicate compounds or compromise formulation stability. That’s why investing in a proper pipeline and tank heating system isn’t a luxury — it’s essential for maintaining process consistency and compliance.

Common challenges the Axair team comes across include viscosity control in transfer lines, heat loss in long or outdoor pipe runs, and uneven heating in storage tanks.

Starting with viscosity control in transfer lines: if a syrupy fluid or dense suspension is being moved, even a small temperature drop can turn a smooth transfer into a slow trickle. Properly applied heating keeps viscosity stable and flow rates predictable.

Heat loss in long pipe runs is another issue. Pipelines running through unheated areas or exposed external sites can lose heat quickly, especially during a British winter. Without active heating, products may arrive at the wrong temperature — or worse, freeze altogether.

Then there’s uneven heating in storage tanks. Large tanks can develop temperature layers, with cooler product at the bottom and warmer material at the top. This “thermal stratification” can cause separation or settling, affecting product quality and consistency.

There’s no one-size-fits-all solution for process heating, but there are clever technologies that make life a lot easier.

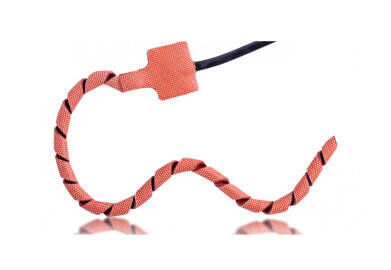

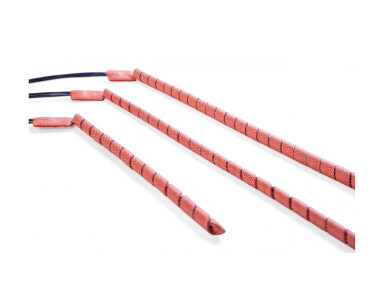

Specifying Spiral Heaters for Complex Pipework

In real-world facilities, pipelines rarely run in straight lines. They twist, turn, and squeeze through tight plant layouts. Spiral heaters are built to handle that complexity. They wrap neatly around pipes — even those with bends and junctions — delivering even heat across every surface. A standard spiral strip can extend up to 1000mm, offering generous coverage, and bespoke options are available for unique applications.

Spiral Heaters in Action

In one UK pharmaceutical plant, Axair’s spiral heaters are used on transfer lines carrying temperature-sensitive liquid excipients. By maintaining the product just a few degrees above ambient, the heaters keep the fluid mobile without overheating it — and without adding bulky insulation or requiring pipework modifications.

Available in multiple diameters and built for demanding environments, spiral heaters combine durability with precision, making them ideal for pharmaceutical, food, or chemical processes where reliability matters.

Specifying Kapton Heaters When Space Is Tight

Sometimes precise, gentle heat is needed in a compact space, like inside an analytical instrument, a diagnostic device, or a small bench-top system. Kapton heaters are well-suited to these applications, offering ultra-thin, flexible, pinpoint temperature control.

Kapton Heaters in Application

In a laboratory preparing biological samples, Kapton heater mats are used to keep small reagent reservoirs at a constant temperature. The heaters are so thin they fit under the vessel without affecting its size or weight, yet they maintain an exact temperature for hours at a time.

Kapton heaters are also popular in research and testing facilities where space is limited and thermal precision is critical, such as maintaining temperature stability in optical systems or sensor housings.

These two act as hero products for the industry much of the time, but the surface-heating range is vast and ever extending as new technologies and processes are introduced. The Axair team is always available to discuss heating applications and help identify the best heating solution.

Flexible silicone heaters are effective for wrapping around tanks and pipes, providing even, adjustable heat to keep liquids flowing and prevent crystallisation.

Ceramic heater mats are designed for high-temperature or high-viscosity materials, delivering powerful, even heat while withstanding demanding conditions.

Preformed heaters are custom-shaped to fit curved equipment or drums, ensuring consistent contact and uniform heating.

Good temperature control doesn’t just protect products — it saves energy, reduces maintenance, and prevents downtime. By understanding a system’s specific thermal requirements and selecting heating solutions tailored to the process, temperature challenges can be transformed into smooth, reliable operation.

For organisations dealing with stubborn viscosity, uneven tank temperatures, or process lines that lose heat too quickly, it may be time to reconsider the heating strategy. Axair’s heating specialist, Robert Burn, is available to discuss the right heating solution for any lab or manufacturing setup — helping products, pipelines, and processes perform exactly as they should.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh