Laboratory products

Probe Polishing Process Reduces Carryover by up to Seventy Five Per Cent

Mar 21 2017

The DP3® polishing process from Diba Industries, Inc improves the performance of stainless steel and other metallic probes used for IVD and diagnostic instruments. Diba’s proprietary process creates an extremely smooth and durable internal surface that reduces carry-over by up to seventy five per cent.

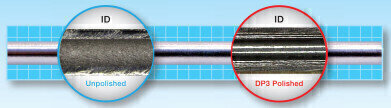

DP3 polishing can greatly improve surface finish on the internal diameter (ID) of a probe. This reduces microscopic pits where process fluids may collect, minimising the possibility of cross contamination. The surface improvement may also positively impact wash characteristics, thereby reducing cycle time and wash fluid costs. Unlike similar processes, which apply a coating that can flake off over time, DP3 treatment results in an ID surface finish that is highly durable. The DP3 process is available on probes with inside diameters down to 0.016” in flush or angle-cut tip designs.

When coupled with Diba’s proprietary probe draw down process to reduce tip ID while maintaining a smooth inner surface, DP3 enables precise dispense and aspirate functions for the most demanding new more sensitive diagnostic reagents. Diba application engineers work closely with OEM instrument designers to customise probe manufacturing capabilities according to the needs of each instrument and application.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh