Pipettes

Pipette calibration – working mode of RADWAG balances 2Y series

May 02 2012

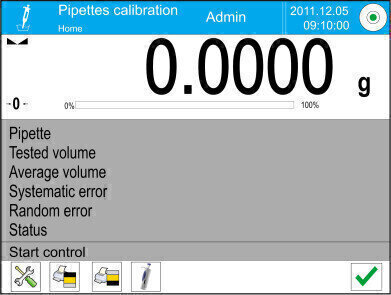

Radwag balances 2Y series have already been described in the Labmate magazine. Among the breakthroughs available in the 2Y series, there is the pipettes calibration mode dedicated to calibration and checking of single and multichannel automatic piston pipettes. The function is available in RADWAG microbalances and standard analytical balances 2Y series.

The Pipette Calibration mode is dedicated to determining measurement errors of volume in piston pipettes, in accordance with standard ISO 8655 or according to user requirements. It is combined with the database of pipettes, which includes complete specification of pipette’s parameters and permissible errors value.

The working mode enables:

• Calibrating pipettes with fixed or adjustable volume, single or multi- channel;

• Preparing a database of pipettes including: pipette name, code, tested volume and others;

• Calculating results on basis of:

- Average volume of a pipette (channel)

- Systematic error es (accuracy error)

- Random error CV (repeatability error)

• Carrying out automated measuring procedures with consideration of pipette’s type;

• Acquiring calibration results to a database (in a form of reports from calibration process);

• Printing reports from pipette calibration process

• Exporting reports from tests

During volume testing procedure, the software determines accuracy and repeatability errors for tested volume. In case of pipettes with adjustable volume, the software enables declaring up to 5 volume from total pipette’s range, that are checked during calibration process.

In order to ensure the highest accuracy of pipettes calibration process, it is recommended to maintain stable ambient conditions, including temperature (between 20°C - 25°C with change rate during testing within ± 0.5°C) and relative humidity between 50-75 %. Additionally, a pipette, tips and distilled water should be acclimatized for temperature for at least 2 hours before calibration/testing process.

Pipettes calibration mode is available either on dedicated balances, like MYA/2Y 21/P or on standard analytical balances 2Y series. In case of the latter, an optional adapter for pipettes calibration in installed inside balance’s weighing chamber. The adapter (see picture) is a simple supplementary device dedicated for calibration and checking of piston pipettes. It has been designed to minimize evaporation occurring in liquid handling procedures and consists of a minimized weighing chamber installed inside the weighing chamber of a balance. The adapter features an evaporation ring and a dedicated weighing pan for central locating of the measuring vessel. Small dimensions of the adapter, combined with the evaporation ring enable maintaining high humidity rate inside the weighing chamber and the measuring vessel, thus stopping liquid evaporation process. Carried out research proved that the adapter for pipettes calibration eliminates or considerably reduces liquid evaporation process, which is essential for correct gravimetric calibration of piston pipettes.

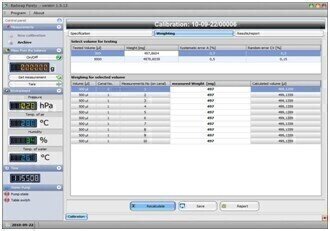

Pipettes calibration mode can be supported by RADWAG Computer software PIPETTES which also complies with the requirements of standard ISO 8655. The software supervises the complete process of pipette calibration creating an easy-to-use system.

The offer is complemented by RADWAG single channel automatic piston pipettes with fixed and adjustable volume. The pipettes join excellent measuring parameters with reasonable price.

For more information on pipettes calibration mode read an article on pipettes calibration or contact your local RADWAG dealer.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh