IT solutions

Saniswiss aHP - a safer alternative in surface decontamination

Nov 21 2019

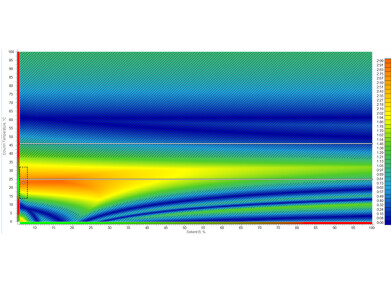

A recent study in the Applied Bio Safety Journal of ABSA International concluded that Saniswiss plasma activated aerosolized hydrogen peroxide (aHP)consistently inactivated bacterial growth from biological indicators containing at least 10- 6 Spores of Geobacillus stearothermophilus placed on stainless steel discs wrapped in Tyvek pouches. It further concluded that the biological indicators placed at various locations in a class 2 biosafety cabinet were equally inactivated, showing that hydrogen peroxide aerosols migrate through HEPA Filters.

The study summarised that Saniswiss automate AHP is “a safer alternative in surface decontamination, especially if used for frequent treatment of hospital or laboratory rooms” “aHP proved to be an efficient, easy to set up and cost effective method to decontaminate rooms and BSC’s potentially contaminated with organisms. Indeed, the cost of the aHP generator is 10 to 20 times lower than HPV or VHP generators. It is quick to set up, environmentally friendly (hydrogen peroxide degrades into oxygen and water ) and well tolerated by standard laboratory equipment, including electronics.

aHP will probably become a method of choice in the near future.

Simplicity for Safety

Saniswiss offers two different formulations to be used with the automate aHP. A preventative option for daily use of the machine and a curative option for punctual outbreaks, respectively bio sanitizer aHP p (6% of boosted Hydrogen Peroxide and biosanitizer aHP c (12% of boosted Hydrogen Peroxide ). Both products are eco friendly, non toxic, non corrosive, non halogenic and leave no residue without generating germ resistance.

Efficacy

Up to a log 6 reduction, our solutions have a powerful lethal activity against a wide range of pathogens including virus, bacteria, yeast, mould, spores and MDR super bugs. active as a system according to NFT 72281 biocide TP2. Before use read the label and the product information. Use biocides with caution.

Reliable and reproduceable

Simple

The simplicity of the process makes the automate aHP the perfect tool to implement in your IPC process. Operators simply place the automate aHP in the corner of a room select the appropriate volume and press the “on” button before leaving the room.

Dry Mist

The vortex created by the automate aHP will spread our bio solution everywhere, and the million sub microns will ensure an optimal disinfection through oxydation. The dry mist is perfectly compliant with any electrical devices, as well as materials sensitive to humidity such as paper. Therefore no new pre installation operations need to be done before use , saving time and complexity for operators.

Short Cycle

Depending on the size of the room the automate aHP will spread the aerosol for a few minutes and then automatically stop when done. The evenly spread dry mist will need a contact time of 30 minutes in order to reach its full efficacy. Finally, depending on the available air flow (windows, doors, ventilation system) operators will need to ventilate the room for a few minutes in order to recover it. The approximate full cycle time for daily use is usually about 45 minutes in total.

For further information please click here.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh