Autoclaves

Small changes create a huge impact

Sep 11 2024

As an increasing number of laboratories and research institutions take the lead in decarbonization and sustainability efforts within their organisations, it becomes increasingly important to match your autoclave to your workload. Most research labs rely on autoclaves to ensure that their equipment, reagents, glassware, and other tools are sterile. Autoclaves utilise a combination of steam/pressure/time, to reliably kill or deactivate harmful bacteria, viruses, fungi, spores, and pathogens on lab items or in waste loads before disposal.

Steam-jacketed autoclaves are ideal for the most intense high-throughput environments, such as hospitals, because they have the workload to complete over 12 cycles in a workday. Jacketed autoclaves use large amounts of water and energy because they are optimized for around-the-clock operation. However, this throughput isn’t always necessary for research environments. Whilst some labs might work at a furious pace, the majority do not. This is where a non-jacketed autoclave can greatly outperform its jacketed autoclave equivalent. On average, without any added water-saving features, jacketed autoclaves typically use between 166 litres and 190 litres of water per sterilization cycle, depending on cycle type. The equivalent non-jacketed autoclave uses less than 8 litres of water per cycle, regardless of cycle type.

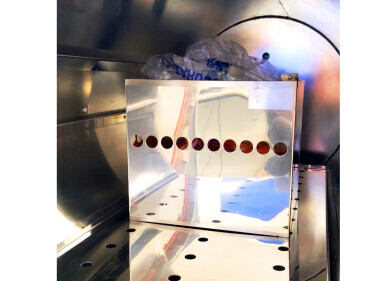

Even the shape of the chamber can have a huge impact. If you don’t plan to sterilise flat trays of medical instruments regularly, then you don’t need a rectangular chamber! On an annual basis, a cylindrical-vessel front-loading autoclave, such as Priorclave's EH400-SMART 400 Litre autoclave can be expected to use a sixth or less as much water and energy when compared to an almost identical rectangular model autoclave—that’s added savings on top of the lower initial purchase price. By eliminating corners, the cylindrical vessel also improves steam circulation, preventing cold pockets and assuring complete sterilization without excessive cycle times or chronic failed loads.

Correctly pairing the right type of autoclave to your potential workload will save you time, water, and electricity. Our global network of exclusive distributors and factory-certified authorised service agents (ASAs) are fully supported by Priorclave to handle every aspect of steam autoclave specification to ensure the perfect match. Most importantly, your local Priorclave distributor is intimately familiar with the on-the-ground realities within your region, from water quality and power-grid stability issues, to regulatory and statutory minutia. To discover just how affordable and impactful a Priorclave autoclave can be, contact today or visit the website to find your local distributor.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh