Autoclaves

Built for Safety, Priced for Affordability

Jun 03 2025

Priorclave is one of the very few autoclave manufacturers in the World that retain complete control of their supply chain, manufacturing all critical components in-house. This vertical integration is central to achieving exceptional process reliability and cost-effectiveness while fulfilling high safety and performance criteria. Notably, the company’s dedication to rigorous safety standards informs every aspect of its autoclave design.

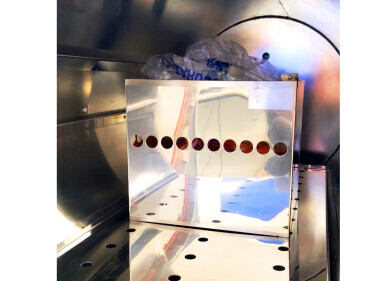

Every cylindrical chamber produced is constructed from type 316 stainless steel, an austenitic alloy enhanced by molybdenum to improve corrosion resistance and mechanical toughness. A bespoke seam welding system is employed to produce seams characterised by superior alignment, smoothness, and long-term durability, ensuring consistent performance under repeated sterilisation cycles.

In addition to material innovations, every autoclave is equipped with integrated thermal and pressure lock mechanisms within the door assembly. These locks prevent inadvertent opening under unsafe temperature or pressure conditions, thereby enhancing operator safety.

Externally, the autoclave is finished with an epoxy coating augmented by a silver-based antimicrobial agent. This inorganic, non-leaching treatment offers long-term protection against bacterial contamination. Empirical data indicate that this coating can reduce bacterial growth by up to 99.99%, demonstrating efficacy against pathogens such as MRSA, Escherichia coli, Listeria, Legionella, Campylobacter, Salmonella, Pseudomonas, and over 50 additional microbial species. The technology’s non-leaching nature mitigates the risk of bacterial resistance development—a significant advantage over traditional organic antimicrobial agents.

Priorclave offers an extensive portfolio that includes over seventy standard designs, with configurations available in BASE, SMART, and PERFORMANCE variants, as well as bespoke solutions tailored to your specific laboratory requirements. Each autoclave is integrated with Priorclave’s exclusive Tactrol3® controller, which enables single push-button operation (ensuring usability even when operators are wearing gloves) and advanced programmability to optimise sterilisation protocols for a variety of media.

This integrated approach—spanning material science, precision engineering, and safety-focused design—exemplifies a holistic methodology in laboratory autoclave development. The combined effect of robust construction, innovative antimicrobial treatments, and advanced control systems not only contributes to operational safety and reliability but also supports a sustainable maintenance strategy through comprehensive warranty and service agreements, which are some of the most supportive and comprehensive warranty and service agreements in the World.

The innovations incorporated into the Priorclave autoclave design represent a significant advance in laboratory sterilisation technology. By harmonising cost-effectiveness with stringent safety and performance standards, Priorclave’s autoclaves offer laboratory professionals a dependable solution for routine and research applications alike.

To discover your nearest distributor, or to learn about all the safety benefits of owning a Priorclave autoclave and which model would be perfect for your needs, contact Priorclave's sales team.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh