-

The Laser at STFC's facility (CLF) based in the Rutherford Appleton Laboratory

The Laser at STFC's facility (CLF) based in the Rutherford Appleton Laboratory

News

Ironing Out Metal Defects

Jan 28 2018

A new tool being developed by laser experts at the Science and Technology Facilities Council’s (STFC) Central Laser Facility (CLF) aims to develop unique methods of treating metals for use in high-value manufacturing, for example in high stress machinery such as aerospace components, with much greater precision and in just a fraction of the time of traditional methods.

Powerful nanosecond pulses delivered to the metal target by the laser compresses the atoms in the metal leaving the structure locked in a compressed state, making it much more resilient and resistant to cracks.

Dr James Nygaard, development laser scientist at CLF, said: “At CLF our lasers are among the most powerful in the world and have been used for a wide range of research such as probing the internal structure of matter under extreme conditions.

“We can harness the power of these laser technologies to solve real-world engineering problems and through the development of the laser shock peening technique there is potential to revolutionise the way metals for high-stress machinery are manufactured.”

The concept is similar to the traditional blacksmith’s hammer, but using a pulsed laser allows us to target precise areas on a structure – for example, the laser can be targeted at welds to add strength – and the compressive shockwave can be tailored by adjusting the laser parameters.

The laser shock peening technique is of specific importance to high-value sectors including nuclear power generation and aerospace, where aircraft engine fan blades can be laser peened to make improve their resistance to bird strike.

This new tool is powered by the in-house laser platform DiPOLE (Diode Pumped Optical Laser system for Experiments).

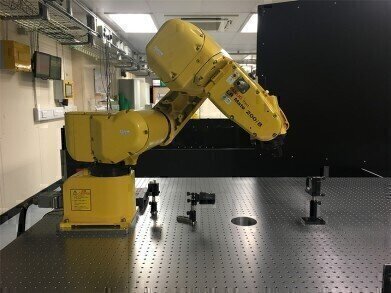

John Collier, Director of CLF, said: “This is the latest application to be developed by the team at CLF where we have used the experience of our laser experts to address potential problems for industry. Our next step will be to automate the technology using robotics to enable the treatment of large engineering components – this will save time and reduce costs, making the technique more broadly attractive to industry.”

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh