-

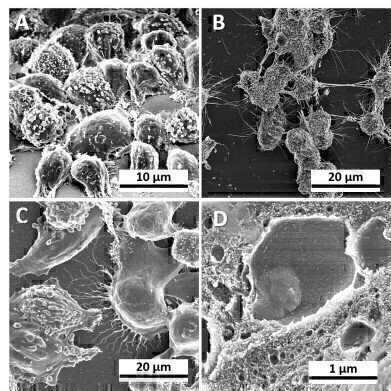

Cell on protein membrane, SEM. Credit: Bioprinting

Cell on protein membrane, SEM. Credit: Bioprinting

News

3D Printed Membranes to suit any Lab

Aug 19 2021

For scientists studying how two different types of cell can influence each other, a simple model would be to isolate and separately culture two cell populations on a conditioned medium. One cell group would then be transferred onto the same growth medium of the second cell population to study interactions occurring. However problems can arise if the molecules of the introduced cell population are too short-lived to stabilise in the culture medium for long enough for transfer to the acceptor cell group. This would mean an absence of feedback signals existing in natural conditions.

Researchers of the Cell Signalling Regulation Laboratory at the Moscow Institute of Physics and Technology (MIPT) have developed a co-cultivation system that is said to be low-cost and reproducible compared to some of the existing systems. Based on a polymerized BSA membrane, its size and relief are determined by a mould created using a 3D printer. The possibility of co-cultivation is achieved with magnetic nanoparticles (NPs), cross-linked into the membrane, which allows it to be kept afloat in a culture liquid using a constant magnetic field.

Lead scientist Ilia Zubarev, senior research fellow at the MIPT Cell Signaling Regulation Laboratory, said: “We decided to create a matrix based on a cross-linked protein. Such systems are often used to simulate biological matrices. To achieve the possibility of co-cultivation of various cells, we chose an original solution that had not been used before. To maintain the protein membrane above a certain height inside the vessel, we decided to saturate it with magnetic nanoparticles. As the main component of the membrane, Bovine serum albumin (BSA) was chosen. This protein is non-toxic, widely available, is actively used in various fields of biology and as a rule, is already available in any laboratory.”

Cells cultivated on the membrane were found to have retained their viability and divisional capability, the membrane could be fixed for histochemical or immunocytochemical staining and the cells were able to be separated from the membrane for further study, the researchers said.

Zubarev added: “At the bottom of the Petri dish, as on the membrane, different types of cells were grown. The membrane with cells were kept afloat in the culture medium. For several days, the cells exchanged signals with each other and after that it was possible to assess their mutual influence.

Such a co-cultivation system can be manufactured in any laboratory, and it is a cost-effective alternative to commercial alteratives for cell co-cultivation."

The 3D printing method allows to flexibly and quickly adjust the manufacturing process to the needs of a particular laboratory. Such protein membranes can be made in any laboratory using a 3D printer and widely available general laboratory reagents.

The research was supported by the RNF grant 19-74-00081.

The study was published in the journal Bioprinting.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh