Mass spectrometry & spectroscopy

MIT researchers develop compact laser comb to identify chemicals with high precision

Aug 26 2025

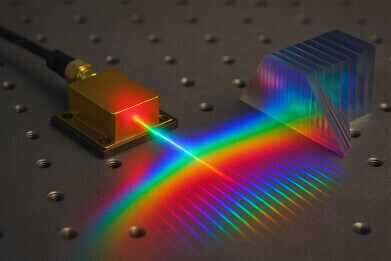

Optical frequency combs are lasers that can act like rulers to measure specific frequencies of light with high accuracy. Scientists can use them to detect and identify chemicals and pollutants with extreme precision. Frequency combs have long been regarded as promising tools for portable spectrometers and remote sensors because they can deliver real-time monitoring of multiple compounds without complex moving parts or external apparatus.

However, it has been difficult to develop frequency combs with a bandwidth which is wide enough for these applications. Many existing designs require large external components that restrict performance and prevent scalability.

However, a research team at the Massachusetts Institute of Technology (MIT), Cambridge, Massachusetts, has reported their compact, fully integrated device that uses a carefully engineered mirror to generate a stable, broad-bandwidth frequency comb. The mirror, combined with an on-chip measurement system, offers the scalability and flexibility required for mass production.

This development has the potential to improve environmental monitoring devices that can detect multiple harmful chemicals from trace gases in the atmosphere.

“The broader the bandwidth a spectrometer has, the more powerful it is, but dispersion is in the way. Here we took the hardest problem that limits bandwidth and made it the centrepiece of our study, addressing every step to ensure robust frequency comb operation,” said Dr. Qing Hu, Distinguished Professor of Electrical Engineering and Computer Science at MIT, principal investigator in the Research Laboratory of Electronics, and senior author of the paper.

The lead author of the study was Dr Tianyi Zeng, alongside Dr. Yamac Dikmelik of General Dynamics Mission Systems headquartered at Chantilly, Virginia, Dr Feng Xie and Dr Kevin Lascola of Thorlabs Quantum Electronics of Jessup, Maryland, and Dr David Burghoff, an assistant professor at the University of Texas at Austin.

An optical frequency comb produces a spectrum of equally spaced laser lines that resemble the teeth of a comb. Scientists can generate combs from various lasers depending on wavelength. Long wave infrared radiation, produced by a quantum cascade laser, allows high-resolution sensing and spectroscopy.

In dual-comb spectroscopy, the beam of one comb travels directly to a detector, while the beam of a second comb passes through a chemical sample before striking the same detector. Comparison of the two beams reproduces the chemical features of the sample at lower frequencies, where signals are easier to analyse. For accurate results, combs must have very high bandwidth. Without it, the devices can only measure a limited frequency range of compounds, increasing the risk of false alarms or incomplete data.

Dispersion – the spreading out of light waves as they pass through a medium – is the major factor that restricts bandwidth. When dispersion occurs, laser lines are no longer evenly spaced degrading the formation of a frequency comb.

“With long wave infrared radiation, dispersion will be very high. There is no way to get around it, so we have to find a way to compensate for it or counteract it by engineering our system,” said Hu.

Hu’s group had previously addressed dispersion in a terahertz laser comb by designing a double-chirped mirror (DCM), a mirror constructed from multiple layers of varying thickness. The corrugated structure of the DCM compensated effectively for dispersion.

“We tried to borrow this trick and apply it to an infrared comb, but we ran into lots of challenges,” said Hu. Infrared radiation has wavelengths ten times shorter than terahertz waves, making fabrication far more difficult. The researchers needed extreme precision to construct the layers and to coat the mirror with a thick gold layer to dissipate heat which could deform the structure through expansion.

They also had to redesign their measurement platform to work with infrared waves, which have frequencies ten times higher than those of terahertz radiation.

“After more than two years of trying to implement this scheme, we reached a dead end,” said Hu. But a breakthrough came when the group realised that the mirror did not require corrugation for infrared radiation, unlike for terahertz. Instead, they adapted a standard DCM design compatible with infrared, while still facing the challenge of fabricating curved layers to capture the laser beam.

“The adjacent layers of mirror differ only by tens of nanometres. That level of precision precludes standard photolithography techniques.

“On top of that, we still had to etch very deeply into the notoriously stubborn material stacks. Achieving those critical dimensions and etch depths was key to unlocking broadband comb performance,” said Zeng.

The researchers integrated the DCM directly onto the laser to create a compact device. They also developed an on-chip dispersion measurement system that removed the need for external equipment.

“Our approach is flexible. As long as we can use our platform to measure the dispersion, we can design and fabricate a DCM that compensates for it,” said Hu.

Together, the mirror and measurement system enabled the team to generate stable infrared laser frequency combs with bandwidths far beyond those typically possible without a DCM. The researchers have said they intend to apply their approach to other laser systems that could yield even broader bandwidths and higher power outputs for demanding applications.

The work received support from the United States Defense Advanced Research Projects Agency (DARPA) and the Gordon and Betty Moore Foundation.

For further reading please visit: 10.1038/s41377-025-01961-4

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh