-

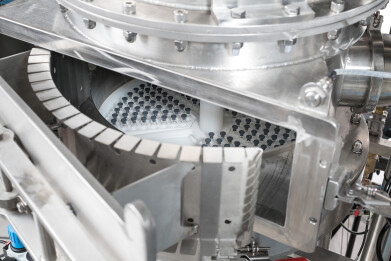

To counteract the high energy consumption of freeze dryers, GEA has introduced the LYOVAC® ECO Mode, which optimises the freeze-drying process with the help of dynamic temperature control of the condenser and regulation of the mushroom valve. This innovation enables significant energy savings without compromising product quality. (Photo: GEA)

To counteract the high energy consumption of freeze dryers, GEA has introduced the LYOVAC® ECO Mode, which optimises the freeze-drying process with the help of dynamic temperature control of the condenser and regulation of the mushroom valve. This innovation enables significant energy savings without compromising product quality. (Photo: GEA) -

The benefits of implementing fast and energy-efficient freeze-drying with microwaves. This technology not only offers advantages in terms of cost and supply efficiency, but also enables continuous processing instead of traditional batch processing. (Photo: GEA)

The benefits of implementing fast and energy-efficient freeze-drying with microwaves. This technology not only offers advantages in terms of cost and supply efficiency, but also enables continuous processing instead of traditional batch processing. (Photo: GEA)

Refrigerators / freezers

Advancing sustainability in pharmaceutical freeze-drying

Oct 08 2024

GEA, one of the world's largest suppliers of systems and components for the food, beverage and pharmaceutical industries, has made important adjustments to take pharmaceutical freeze-drying to an even higher level of sustainability. GEA’s latest developments in freeze-drying technology, helps to optimise production processes, reduce environmental impact and save energy.

One example is the LYOAIR cooling system®, which reduces the environmental impact of the freeze-drying process. Using 100% natural refrigerants and highly efficient compressors, the combination of an air circulation system with a carbon dioxide booster significantly reduces energy consumption compared to conventional systems.

In addition, atmospheric freeze-drying is a technique that can be used to produce so-called lyospheres® without the need for a vacuum. Initial prototypes, although not yet optimised for energy efficiency, have shown that total energy consumption can be reduced to less than 50 percent compared to conventional vacuum freeze-drying methods.

GEA experts also report the benefits of implementing fast and energy-efficient freeze-drying with microwaves. This technology not only offers advantages in terms of cost and supply efficiency, but also enables continuous processing instead of traditional batch processing.

To counteract the high energy consumption of freeze dryers, GEA has introduced the LYOVAC® ECO Mode, which optimises the freeze drying process with the help of dynamic temperature control of the condenser and regulation of the mushroom valve. This innovation enables significant energy savings without compromising product quality.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh

.jpg)

-(1).jpg)

-(1).jpg)