-

Figure 1: The new mixer mill MM 500.

Figure 1: The new mixer mill MM 500. -

Figure 2: The innovative screw-lock grinding jars are easy to handle

Figure 2: The innovative screw-lock grinding jars are easy to handle -

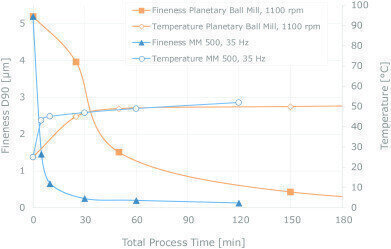

Figure 4: Particle fineness and temperatures during wet grinding of aluminum oxide with 0.1 mm grinding balls of zirconium oxide. The MM 500 was operated without cooling breaks, the total process time therefore equals the net grinding time. 2 h net grinding time was required in the MM 500 to obtain particles of 0.13 µm, whereas 5 h total process time including cooling breaks (1 h net grinding) were required in the Planetary Ball Mill to obtain a particle size of 0.18 µm. The temperature was comparable in both mills.

Figure 4: Particle fineness and temperatures during wet grinding of aluminum oxide with 0.1 mm grinding balls of zirconium oxide. The MM 500 was operated without cooling breaks, the total process time therefore equals the net grinding time. 2 h net grinding time was required in the MM 500 to obtain particles of 0.13 µm, whereas 5 h total process time including cooling breaks (1 h net grinding) were required in the Planetary Ball Mill to obtain a particle size of 0.18 µm. The temperature was comparable in both mills. -

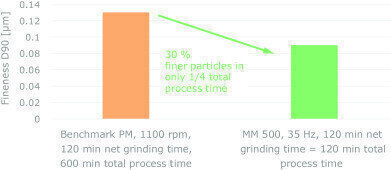

Figure 5: Best grinding result of wet grinding of titanium dioxide with 0.1 mm grinding balls zirconium oxide. The MM 500 was operated without cooling breaks, the total process time is therefore the net grinding time. After 2 h net grinding time the MM 500 produced particles sized 90 nm. In the benchmark planetary ball mill the highest fineness of 130 nm particles was reached after 2 h net grinding time (10 h total process time including cooling breaks).

Figure 5: Best grinding result of wet grinding of titanium dioxide with 0.1 mm grinding balls zirconium oxide. The MM 500 was operated without cooling breaks, the total process time is therefore the net grinding time. After 2 h net grinding time the MM 500 produced particles sized 90 nm. In the benchmark planetary ball mill the highest fineness of 130 nm particles was reached after 2 h net grinding time (10 h total process time including cooling breaks). -

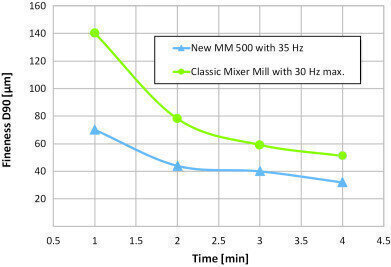

Figure 3: Grinding of basalt (2-5 mm initial grain size) in the MM 500 results in better fineness compared to classic mixer mills thanks to the increased frequency of 35 Hz instead of max 30 Hz (50 ml jar + 12 x 12 mm grinding balls, similar results in 80 ml or 125 ml jars)

Figure 3: Grinding of basalt (2-5 mm initial grain size) in the MM 500 results in better fineness compared to classic mixer mills thanks to the increased frequency of 35 Hz instead of max 30 Hz (50 ml jar + 12 x 12 mm grinding balls, similar results in 80 ml or 125 ml jars)

Mills and grinders

The new mixer mill MM 500 - from fast pulverisation to long-term grindings in the nanometer range

Mar 05 2019

Mixer mills are true all-rounders which are used in laboratories all over the world. These compact versatile bench-top units for dry, wet and cryogenic grinding of small sample amounts mix and homogenise powders in only a few seconds. When it comes to long-term grindings of several hours with high energy input to obtain particles sizes < 1 µm, e. g. for mechanical alloying or chemical reactions, planetary ball mills have been the instruments of choice so far. Despite their benefits for this type of application, they have the drawback of requiring cooling breaks and are not as easy to handle as mixer mills.

Retsch has now introduced the new MM 500 which features a maximum frequency of 35 Hz and is therefore the first mixer mill in the market that generates enough crushing power to produce particles in the nanometer range. As it accommodates 2 grinding jars sized 50 ml, 80 ml or 125 ml and with its suitability for long-term grinding processes up to 99 hours, for the first time a mixer mill will become a real alternative to a planetary ball mill – with more comfortable handling and less warming effects.

Safe and easy operation

The MM 500 provides maximum operational convenience and safety. The innovative design of the screw-lock grinding jars ensures optimum exploitation of the usable volume; the lids are easily screwed, closing the jars tightly for applications like wet grinding and mechanochemical reactions up to 5 bar. The jars are easily inserted into the user-friendly clamping system and may even remain in the system for extraction of a sub-sample or a quick visual check of the sample. A large 4.3-inch touch display enhances operating convenience. By using the new RETSCH-App, the user can control the mill via smart phone or tablet, create application routines, access the Retsch application database or get in touch with the Retsch service team.

High energy input results in high final fineness

The application examples in this article show impressively that the new MM 500 achieves extraordinary grind sizes thanks to the increased frequency of 35 Hz, whereas classic mixer mills usually have a maximum frequency of 30 Hz or even less. Thus, those mixer mills are not suitable for applications which require high energy input. Figure 2 shows the influence of the higher energy input on the final fineness after grinding basalt for a few minutes. The influence of the additional 5 Hz is very impressive in the first 2 minutes where the particles obtained at 35 Hz are factor 2 smaller than at 30 Hz. Additionally, the MM 500 accommodates two jars with a maximum usable volume of 42 ml each which is twice the amount a smaller mixer mill can process but comes close to what is possible with planetary ball mills. The following examples demonstrate that the new MM 500 is perfectly suited for applications which are traditionally performed in planetary ball mills, like ultra-fine grinding down to <100 nm.

Pulverisation in the nanometer range without heat build-up

Typical process times for ultra-fine grinding are several hours; in conventional ball mills additional time for grinding breaks to avoid over-heating of the sample must be added. In contrast to planetary ball mills, the new MM 500 produces particles in the nanometer range without requiring any cooling breaks; the grinding mechanism based on impact rather than friction generates less heat and is more effective than that of a planetary ball mill. The example in Figure 3 shows that the temperature inside the grinding jars, while grinding aluminium oxide, is very similar in the MM 500 and the planetary ball mill - with the difference that the planetary ball mill requires a 4-minute break after each minute of grinding. Otherwise, the temperature inside the jar could rise to 100°C already in the first few minutes of the grinding process. The maximum achievable grind size of 0.14 µm of the aluminium oxide sample was achieved much quicker in the MM 500 than in the benchmark planetary ball mill (2 h instead of 5 h process time). Another example for ultra-fine grinding is shown in Figure 4: grinding of titanium dioxide resulted in much better fineness in the MM 500 (90 nm) compared to the benchmark planetary ball mill (130 nm) in only a quarter of the time.

Conclusion

The new MM 500 is the perfect combination between a classic mixer mill and a planetary ball mill. On one hand, it achieves excellent grinding results within a few minutes, on the other, it is powerful and robust enough to carry out long-term grindings of many hours, for example for mechanical alloying. On top of that, uncomplicated handling ensures safe operation.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh