Mass spectrometry & spectroscopy

New flow cell enhances in-line liquid analysis for process control

Oct 16 2024

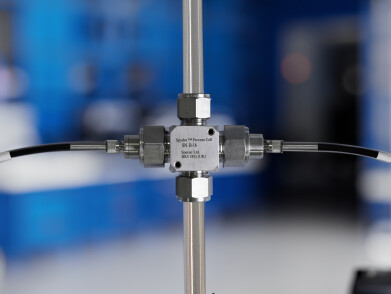

Specac is proud to announce the official release of the Spyder™ Process Flow Cell, an innovative and robust tool designed for laboratory and small-scale pilot plant use. This latest product in Specac’s Process Analytical Technology (PAT) range simplifies real-time, in-line liquid analysis in continuous chemical processes, providing a practical and optimal solution for early-stage process development.

Precision and versatility in process control

The Spyder™ Process Flow Cell, when integrated with a near-infrared (NIR) process analyser via fibre optic cables, delivers seamless real-time liquid analysis as products flow through a process stream. Its compact design and adjustable pathlength provide flexibility, enabling users to experiment with different measurement configurations before committing to a fixed setup.

Key Features:

Adjustable pathlength for customisable analysis

The Spyder™ offers an easy-to-use method for varying the pathlength, ideal for optimising spectroscopy setup during early-stage development. Once the optimal configuration is achieved, users can easily switch from PTFE ferrules to stainless steel ones to secure the setup for in-service use.

Built to last

With robust sapphire optics and a 316L stainless steel body, the Spyder™ is engineered to withstand demanding conditions, handling temperatures up to 200°C and pressures up to 30 barg. The FFKM sealing ensures chemical compatibility across a wide range of processes.

Seamless integration

Fitted with standard Swagelok® connectors, the Spyder™ integrates effortlessly into existing setups, ensuring smooth installation and reliable operation.

Plug-and-play for laboratories and pilot plants

Designed with ease of use in mind, the Spyder™ offers a plug-and-play setup that seamlessly fits into laboratory and small-scale pilot plant environments. Its adjustable pathlength allows for in situ calibration, minimising downtime and reducing the need for costly reinstallation.

With its combination of precision, durability, and ease of use, the Spyder™ represents a cost-effective solution, delivering high return on investment by improving process control and reducing operational disruptions.

Robust solutions for challenging process environments

Specac’s technologies are built to perform even in the harshest industrial environments. The Spyder™ ensures operators maintain control of their processes, contributing to greater operational safety and sustainability. The company are proud to support greener technologies through innovative process solutions.

Comprehensive support from feasibility to full-scale production

Specac works closely with your engineering teams to understand your process needs and deliver tailored solutions. Whether you’re in the feasibility stage or scaling up to full production, Specac provides ongoing support for servicing and repairs, ensuring long-term reliability and performance.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh