-

Accurate quantification results you can rely on using the Atlas® Press and APEX™ Quick Release Die.

Accurate quantification results you can rely on using the Atlas® Press and APEX™ Quick Release Die. -

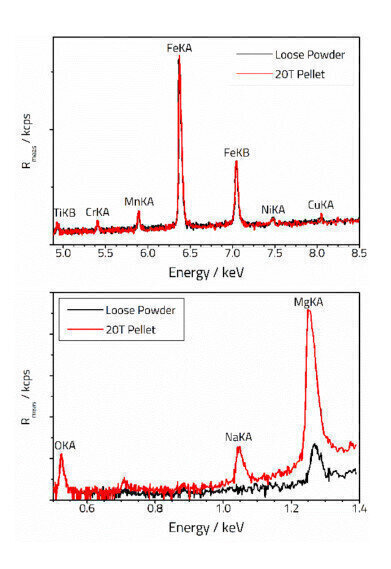

Figure 1: Spectral comparison for (A) heavy elements and (B) light elements in cement samples.

Figure 1: Spectral comparison for (A) heavy elements and (B) light elements in cement samples. -

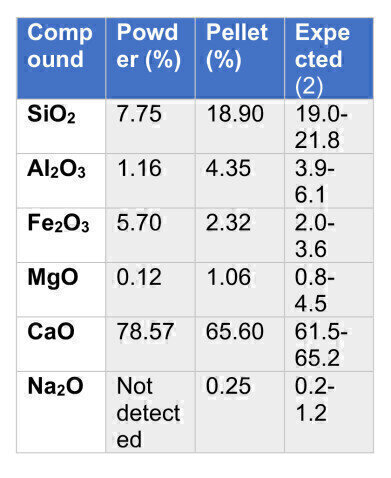

Table 1: Results of Portland Cement fundamental parameter quantification.

Table 1: Results of Portland Cement fundamental parameter quantification.

Mass spectrometry & spectroscopy

Comparing Pressed Pellets to Loose Powder Preparation for XRF Analysis

Jan 14 2021

Factors affecting X-ray analysis

The analytical signal in XRF spectroscopy contains two major components: 1) X-rays emitted at characteristic wavelengths corresponding to electron transitions within the sample atoms; superimposed over 2) a continuous background of X-rays scattered by the outer electrons.

The characteristic X-rays generally emerge from depths on the order of 1-1000 µm below the surface of the sample, with the depth dependent on atomic weight; lighter elements are harder to detect than heavier ones.

Particle size, mineral composition, or density can all affect the intensity of the characteristic emission peaks and increase background scattering. These effects rule out reliable quantification of sample composition [1].

Grinding sample powders to a fine particle size and pressing them into a smooth, flat pellet should reduce scattering and improve the detection of light elements.

Experimental

Samples of Type 1 Ordinary Portland Cement (Dragon Alfa, UK) were used as-purchased.

Loose powder preparation

10 g of sample was placed into an open-ended sample cup and covered with a 6 µm Mylar® film window.

Pressed pellet preparation

The sample was milled and homogenised with 20wt% of cellulose binder (SpectroBlend®) using a planetary ball mill. Pellets were pressed in aluminium sample cups at 20 tonnes using a 25 T Atlas® Power Press and a 40 mm APEX™ Quick Release Die.

Spectral acquisition

Spectra were recorded on a high-throughput wavelength dispersive XRF instrument with vacuum capability.

Results & Discussion

Heavy and light elements

XRF spectra for the loose powders and pressed pellets show clear differences (Figure 1). The lightest element Na is undetectable in the powders, while the signals from Mg, Al, and Si are much reduced. As expected, the signal from the heavier elements such as Fe is not affected.

The samples prepared as pellets show higher signal-to-noise and allow the lightest elements to be detected easily above the background. The detection of light elements is further improved by avoiding the use of thin film coverings, which allows measurement under a vacuum.

Quantification of composition

The ability to clearly detect all the elements in the sample becomes critical for accurate quantification, as can be seen in Table 1. In the powder samples, underestimation of the lighter Al, Mg, and Na elements leads to overestimation of Fe and Ca in the cement. The pellet samples result in a quantification which is within the range established by averaged laboratory experiments.

Conclusions

Loose powder sample preparation is a quick method for the detection of heavy elements, however, quantification is unreliable due to the inability to detect lighter elements.

Therefore, pellet preparation is essential for accurate quantification of sample composition. It allows detection of the lightest elements and prevents underestimation of the other light elements.

References

1. Jenkins, Ron. Quantitative X-Ray Spectrometry, Second Edition. New York : Marcel Dekker, Inc., 1995.

Preparation is the key to success

X-Ray Fluorescence spectroscopy (XRF) is sensitive to the preparation and presentation of the sample material to the instrument. Different sample preparations can yield results that are both quantitatively and qualitatively different from other methods of preparation – but how different?

Contact Specac to discover how pressed pellet sample preparation improves the quality of your XRF spectra and enables accurate quantification to be obtained.

Acknowledgement

Dr Tom Knott, XRF Geochemist at the University of Leicester School of Geography, Geology and the Environment provided the XRF spectra shown here

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh