Laboratory products

Determination of Primary Drying End Point

Apr 09 2010

SP Industries, Inc has issued a new technical note that compares and contrasts different techniques for primary drying end point determination.

Freeze drying is the process of drying a product in a frozen state under vacuum to increase product stability, minimise the effects of oxidation and degradation, and increase the shelf-life of the product. The process has found application for preserving products including biologicals, bacterial cultures, water-damaged documents, tissue preparations, food and therapeutic products such as vaccines, drugs, antibodies and proteins. A critical point in the freeze drying process is when the last drop of solvent has been removed from the sample - the primary drying end point.

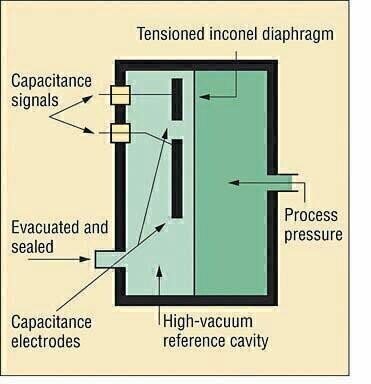

There are two types of vacuum gauges/sensors that are routinely used in modern pilot scale and production freeze drying and lyophilisation equipment. The technical note describes how capacitance manometers and Pirani vacuum gauges work as well as detailing their operational advantages and disadvantages. By taking convergence data from a freeze dryer equipped with both capacitance manometer and Pirani gauge sensors the authors

demonstrate a reliable technique for accurately determining the primary drying end point.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh