-

The MGF X Line range of oil-free compressor supply a continuous and highly reliable source of clean, dry air without risk of contamination.

The MGF X Line range of oil-free compressor supply a continuous and highly reliable source of clean, dry air without risk of contamination. -

The MiniCUBE is the most compact solution in its market segment - small in size but big in benefits.

The MiniCUBE is the most compact solution in its market segment - small in size but big in benefits.

Laboratory products

Oil-Free Compressors Benefit Dental Lab Milling Machines and 3D Printers

Aug 23 2023

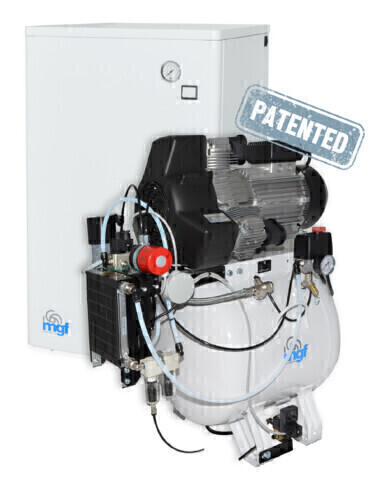

FPS Air Compressors has introduced the innovative MGF X Line range of oil-free compressors to the UK market, offering dental labs utilising CAD/CAM-driven milling machines and 3D printers a reliable source of clean, contaminant-free compressed air.

The rise of Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) systems in dental restoration creation has driven the demand for consistent compressed air. The X Line oil-free compressors ensure a continuous supply of clean and dry compressed air to CAD/CAM-driven milling processes, ensuring precise and reliable production of dental prosthetics.

A key advantage of the MGF X Line compressor technology is its increased air capacity, leading to reduced energy consumption. The patented MGF system minimises air requirements for the membrane dryer, increasing available air flow from the compressor by 20-25%. This enhancement optimises dental lab processes such as milling.

The versatility of the X Line extends to serving 3D printers as well. These printers require compressors that deliver high-quality air and minimal vibration to maintain the precision demanded by the 3D printing industry. As 3D printing becomes more prevalent, air quality's significance in the printing process is on the rise.

The X Line compressors ensure consistent air quality with a 0.01 µm filtration system and an efficient membrane dryer. This provision of clean, continuous air facilitates uninterrupted workflows. With a maximum pressure of 10 bar, these compressors offer constant air flow across a range of models suitable for various applications.

Noise levels are also addressed, with the cabinet-housed X Line compressors boasting low vibration and quiet operation. Alongside the four 'Base' models, three 'Silent' versions are available, producing noise levels not exceeding 53-56 dB(A). Moreover, the durable construction of X Line compressors ensures longevity, minimising total cost of ownership for dental labs.

Ultimately, the MGF X Line brings together efficiency, performance, and reliability while operating quietly, delivering substantial value to dental labs employing CAD/CAM-driven milling and 3D printing.

In addition to the MGF X Line, FPS Air Compressors offers an extensive range of oil-free and SCROLL compressors suitable for various applications across sectors. These include product handling in food and beverage plants, aseptic processes in pharmaceutical facilities, circuit board manufacturing in electronics, air splicing in textile factories, testing instruments in research labs, and analysis devices in environmental monitoring processes.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh