-

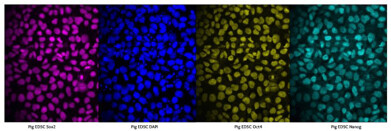

Pig embryonic disc stem cells grown on iMatrix-511 silk recombinant laminin. Images courtesy of Ramiro Alberio, Professor of Developmental Biology, and member of the Future Food leadership team at the University of Nottingham, UK.

Pig embryonic disc stem cells grown on iMatrix-511 silk recombinant laminin. Images courtesy of Ramiro Alberio, Professor of Developmental Biology, and member of the Future Food leadership team at the University of Nottingham, UK. -

Cultured meat – a new era in food technology.

Cultured meat – a new era in food technology.

Laboratory products

Pioneering products for sustainable food development

Jun 14 2024

AMSBIO offers a range of kits, media, and reagents that facilitate the development of food in an environmentally sustainable manner, ensuring minimal resource wastage and no adverse impact on consumer health.

Recent biotechnological advancements have led to the creation of cultured meat - meat grown in a laboratory using stem cell technology. This innovation mimics the texture, flavour, and nutritional value of conventional meat. Cultured meat has the potential to be less resource-intensive, reducing the need for animal husbandry and slaughter, which in turn can decrease air pollution, deforestation, water use and contamination, biodiversity loss, antibiotic resistance, and foodborne illnesses.

AMSBIO’s products for cultured meat research and development fall into three main categories. First, they provide the right environment and stimuli for cultured cells. Second, they offer standards and kits to test if these cells behave like their in vivo counterparts. Finally, they supply cryopreservation media to archive cells for reference or future use. Their range includes skeletal muscle differentiation kits, recombinant extracellular matrices, 3D scaffolds, and cryopreservation media.

Cultured meat production requires a suitable source of cells that can differentiate into muscle and fat cells. A 2023 study by Kalkehi et al. highlighted the challenge of repeated cell harvesting from different animal sources. This was overcome by successfully cryopreserving bovine myogenic cells in CELLBANKER® media from AMSBIO, which maintained cell quality for future production.

Another crucial component in developing new cell-based foods is the culture media and matrix that support cell growth and differentiation. In 2022, Takahashi et al. demonstrated the efficiency of iMatrix-511 Laminin E8 fragments, available from AMSBIO, for the adherence and differentiation of bovine myogenic cells into myotubes. These micropatterned culture substrates formed scaffolds upon which myotubes could align into myofibers, mimicking native muscle tissue structure.

Ongoing research aims to determine the optimal combination of cellular sources, growth media, bioprocesses, and biomaterials to scale up cultured meat production commercially. All materials and procedures used must comply with strict GMP and FDA regulations to ensure consumer safety. The main challenge is the high cost of large-scale production, necessitating standardised procedures and automated processes to reduce costs. AMSBIO aims to ease the transition from bench scale to manufacturing with GMP-compliant products and services.

Readthe blog ‘Cultured Meat: from cell culture to restaurant table’.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh