Chromatography

The truth about nitrosamine testing: Separating real risks from false alarms

Feb 20 2025

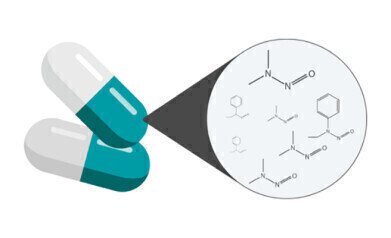

Nitrosamines have become a critical concern across industries, from pharmaceuticals to cosmetics, due to their potential carcinogenic risks. Regulatory agencies, including the FDA and EMA, have introduced strict limits on nitrosamine contamination, requiring manufacturers to adopt advanced detection methods. However, many laboratories struggle with inflated nitrosamine results, often caused by nitrites, which interfere with accurate readings and create compliance challenges.

Nitrites, commonly found as residuals in raw materials and excipients, can react with amines under acidic conditions or high temperatures, forming new nitrosamines over time. This means that even if nitrosamine levels appear low initially, they could increase under certain storage conditions. Traditional detection methods often fail to distinguish between nitrites and nitrosamines, leading to overestimated contamination levels, unnecessary compliance concerns, and time-consuming retesting that delays production. To meet evolving regulatory expectations and minimise unnecessary disruptions, manufacturers need a more precise approach—one that separates nitrites from nitrosamines for true contamination insights.

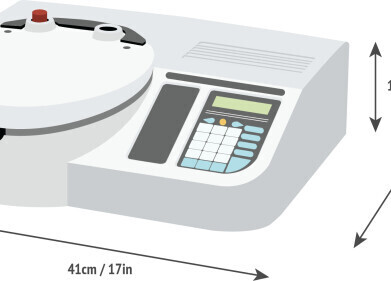

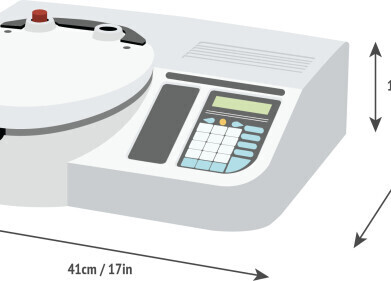

The Automated Total Nitrosamine Analyser (ATNA) has been a trusted tool for labs conducting Total Nitrosamine Content (ATNC) analysis. Now, thanks to a significant advancement in vial chemistry, the ATNA can separate nitrites from nitrosamines, providing a clearer, more reliable contamination assessment. This breakthrough allows laboratories to eliminate nitrite interference, ensuring accurate nitrosamine detection, improving compliance, and reducing unnecessary re-testing. The ATNA’s ability to process up to 120 samples per run makes it ideal for high-throughput environments.

The system’s proprietary vial chemistry isolates and removes nitrites before measuring nitrosamine content separately. By comparing the total and nitrite-free results, labs can quantify the exact nitrite content. This process not only ensures compliance but also helps predict nitrosamine risks under storage and packaging conditions, allowing manufacturers to take proactive measures to prevent contamination.

Accurate nitrite detection isn’t just about meeting regulations - it helps prevent contamination at its source. By identifying excipients with high nitrite levels, manufacturers can choose safer raw materials, prevent costly recalls and reformulations, and improve overall product safety. With this enhanced level of accuracy, the ATNA empowers industries to manage nitrosamine risks confidently and efficiently.

To explore the critical role of nitrite separation and how the ATNA transforms nitrosamine analysis, watch our on-demand webinar at your convenience. Learn how this innovation can improve compliance, reduce unnecessary testing, and deliver more precise nitrosamine detection.

More information online

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh