IT solutions

HAVER online analysis at any time; In any place

Jul 24 2016

Time is also money in bulk material industries. The response time to manufacturing errors has to be minimised as much as possible. Haver & Boecker has developed a HAVER CPA system for online measurement of dry and free-falling bulk material in a measuring range from 34 µm to 25 mm. It is called HAVER CPA 2-1 ONLINE.

The HAVER CPA 2-1 ONLINE is resistant against negative surrounding conditions such as heat, dust and wetness. An integrated cooling cycle system ensures a proven operation even at high temperature operation. An ‘AIR KNIFE’ cleans camera and lighting array of dust deposits regularly with an air blast. An absorbent minimises the formation of condensation at high air humidity.

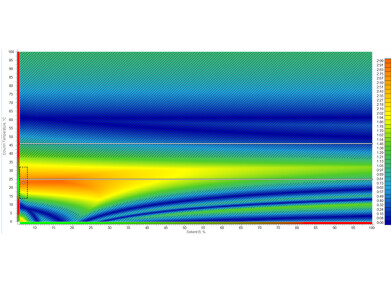

Procedure: The HAVER CPA 2-1 ONLINE is ready for continuous measurement. It is connected with a downpipe sampler, which takes samples without any interruption of production. The sampler and CPA device can be activated manually or by a programmable controller with interchangeable memory. The analysis is based on the proven CPA measuring principle: A high-resolution digital line scan camera scans the particles of free-falling bulk materials against the background of an LED-lighting array. Up to 28,000 line scans per second are combined by the CPA software to form an endless data record. The shadow projections are evaluated and displayed in real time (HAVER REAL TIME). After measurement the sample is returned to the bulk production quantity.

Due to the GigE camera interface a notebook can be placed at a distance of up to 100 m from the analysing process.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh