Autoclaves

Can I autoclave it?

Apr 15 2025

With the vast majority of laboratory items that are sterilized processed in an autoclave, the answer is usually – “yes”. This positive, however, is it is nearly always followed by a “but”, as to achieving quick, effective, and compliant sterilization, and autoclave must be equipped with the correct matrix of components for the material being processed.

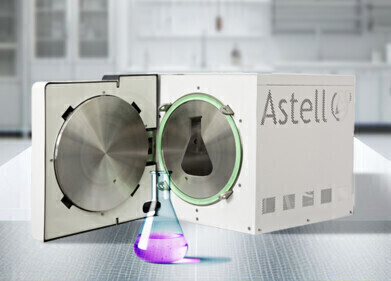

To aid you in your selection of an autoclave, you could do no better than to consult Astell Scientific, a manufacturer of autoclaves since 1884, who have provided examples of some commonly sterilized materials and the autoclave features required to effectively process them in the following.

Media

Loads typically containing agar or liquids often demand extended cycle times since most fluids cool slowly. To enhance processing speed, cooling systems using water (via water coils or a ‘jacket’) or air (via an external or internal fan) can be equipped to an autoclave. When fast cooling, an ‘air ballast’ system may be necessary to prevent media from boiling over due to pressure changes within the autoclave chamber.

Such loads benefit from Load Sensed Process Timing, where the internal temperature of the liquid or a thermally identical surrogate are measured by the autoclave, and its sterilization process is actively recalculated to provide optimal efficiency during sterilization.

Waste or 'Discard'

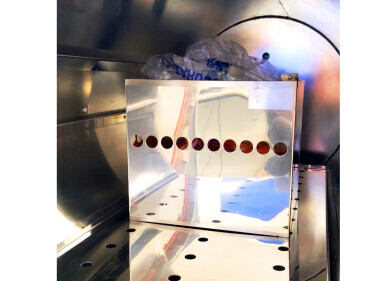

Small quantities of waste with low biohazard risk may only require a simple autoclave with only basic features. A bin of waste, however, is likely to contain many haphazardly placed items, with interstitial spaces that trap air. In these cases, a vacuum system is essential to remove air, and a steam jacket helps improve heat distribution. If these loads contain CL3 / BSL3 biohazards, CAT III compliance options, including HEPA filtration are a prerequisite.

Liquid waste follows slightly different protocols and should be treated similarly to media, but with CAT III biosafety features included where necessary. Due to their heat retention and fluid nature, liquids require enhanced handling procedures. For this reason, Astell’s sister company, AstellBio, produces specialized liquid waste autoclaves that automatically process and dispose of liquid waste.

Laboratory Glassware and Instruments

A basic machine is often sufficient for sterilizing glassware loads, which typically include beakers, flasks, bottles, and cylinders. However, if these items contain liquid, refer to the Media section for further guidance. Autoclavable instruments with simple structures can also be sterilized in an autoclave with only basic components, but instruments with more complex structures such as lumens and tubes may require more advanced setups.

Surgical Packs and Wrapped Instruments

Porous items require a steam generator (or external steam source), vacuum drying, and a heated jacket around the chamber to ensure a touch-dry load at the end of the sterilization cycle.

Animal Bedding and Feed

Similar to surgical packs and wrapped instruments, animal bedding and feed require a steam generator, vacuum drying, and a heated jacket to remove all moisture and ensure a touch-dry load at the end of the sterilization cycle.

Astell also manufactures autoclaves for sterilizing a wide range of other materials, including blister packs, contact lenses, soil, and filters.

For more guidance, explore our product range using the filter products feature. For free advice and a personalized recommendation on the best autoclave for your needs, please contact us.

Digital Edition

Lab Asia Dec 2025

December 2025

Chromatography Articles- Cutting-edge sample preparation tools help laboratories to stay ahead of the curveMass Spectrometry & Spectroscopy Articles- Unlocking the complexity of metabolomics: Pushi...

View all digital editions

Events

Jan 21 2026 Tokyo, Japan

Jan 28 2026 Tokyo, Japan

Jan 29 2026 New Delhi, India

Feb 07 2026 Boston, MA, USA

Asia Pharma Expo/Asia Lab Expo

Feb 12 2026 Dhaka, Bangladesh