Laboratory Products

Different Measuring Techniques Provide Different Results – But What is the Truth?

Aug 29 2017

Author:

Kai Dueffels

on behalf of Microtrac Retsch GmbHThe most common techniques to determine the particle size distribution are dynamic image analysis (DIA), static laser light scatter-ing (SLS, also called laser diffraction) and sieve analysis. This article presents the advantages and drawbacks of each technique, their comparability among each other as well as detailed application examples.

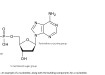

Each method covers a characteristic size range within which measurement is possible. As shown in Figure 1, these partly overlap. The three methods discussed here, for example, all measure particles in a range from 1 µm to 5 mm. However, the results for measuring the same sample can vary considerably.

This article will help to interpret the informative value and significance of particle analysis results and to decide which method is best suited for a particular application. The analysers used for the measurements presented in this article are sieve shakers (Retsch), image analysis systems CAMSIZER® P4 and CAMSIZER® X2 (Retsch Technology) and laser granulometer Horiba LA-960.

Figure 1. Measuring ranges of different methods

Sieve Analysis: Committed to Tradition

Sieve analysis still is the traditional and most commonly used method for particle size determination. A sieve stack consists of several sieves with increasing aperture size stacked upon each other and the sample is placed on the uppermost sieve. The stack is clamped to a sieve shaker and set into vibration for a period of time. As a result, the particles are distributed to the sieves in the stack (fractions) according to their size. Ideally, the particles pass the smallest possible sieve aperture with their smallest projection surface. Taking cubic particles as a model, this corresponds to the edge length of the cube. For lenticular particles, the size determined by sieve analysis would be a value between the thickness and the diameter of the lense, as the particle is oriented diagonally towards the sieve aperture (Figures 2 and 3). Hence, sieve analysis is a technique which measures particles in their preferred orientation with a tendency to determine mostly the particle width.

Figure 2. Model of a measurement of lenticular particles with sieve analysis and DIA. The lense falls diagonally through the smallest possible sieve aperture. DIA ‘sees’ the lense larger or smaller, depending on its orientation. This results in different particle size distributions: the red curve shows the DIA result, the black curve represents sieve analysis results.

Sieve analysis is carried out up to a point where the sample mass on the respective sieves no longer changes (= constant mass). Each sieve is weighed and the volume of each fraction is calculated in percent by weight, providing a mass-related distribution. The resolution of sieve analysis is limited by the number of obtainable size fractions. A standard sieve stack consists of a maximum of 8 sieves which means that the particle size distribution is based on only 8 data points. Automation of the procedure is hardly possible which makes it rather time-consuming. The single steps of sieve analysis are: initial weighing, 5 - 10 minutes sieving, back weighing, and cleaning of the sieves. The most common sources of error are: overloading of the sieves (blocking of sieve apertures, too coarse results); old, worn or damaged sieves (too fine results); or errors in data transfer. It should also be taken into account that the aperture sizes of new standard-compliant sieves are also subject to certain tolerances. The average real aperture size of a 1 mm sieve, for example, is permitted to deviate about ±30 µm, for a 100 µm sieve it is ±5 µm (i.e. the average real aperture size lies between 95 and 105 µm). However, this is just the mean value which implies that some of the apertures can be even larger. With sufficient sieving time the particles find the largest apertures which results in particles larger than the nominal aperture size of the sieve passing through. Thus, the sieve becomes effectively larger than the nominal aperture size indicates. These tolerances are particularly apparent in sieve analysis results of spherical samples or samples with a narrow particle size distribution, as can be clearly seen in Figure 4 which shows the measurement results of a sample of glass beads.

Figure 3. Model of a measurement of cubic particles with sieve analysis and DIA. Sieve analysis determines the edge length whereas DIA measures the edge length or, depending on the orientation of the particle, a higher value (max. edge length * square root of 2 of the hexagonal projection), but never smaller than the value obtained by sieve analysis. Red curve = measurement with DIA, black curve = sieve analysis.

In addition to the dry sieving procedure with wire mesh sieves described in this article, there are other special methods such as wet sieving or air jet sieving.

Dynamic Image Analysis (DIA): What You See is What You Get

For particle characterisation there are two techniques of image analysis. Static image analysis is basically a microscope which measures the sample placed on an object slide step by step. Although the quality of the images is very good and the optical resolution quite high, this method has some decisive drawbacks with regards to representing particle size distributions: the size range is limited, the procedure is rather time-consuming and the quantity of analysed particles is often not sufficient to obtain a statistically sound statement about the entire sample. Consequently, we will only discuss dynamic image analysis in this article. This technique involves a flow of particles which is passing a camera system in front of an illuminated background. Figure 5 shows a schematic of this measurement principle as implemented in the CAMSIZER® X2. The system measures free falling particles as well as suspensions and also features dispersion by air pressure for those particles which tend to agglomerate. Modern DIA systems analyse more than 300 images per second in real time, detecting millions of individual particles within only a few minutes. This performance is based on fast cameras, bright light sources, short exposure times and powerful software.

In contrast to sieve analysis DIA measures the particles in a completely random orientation. A variety of size as well as shape parameters are determined based on the particle images. Typical size parameters are, for example, breadth, length and diameter of equivalent circle (see Figure 6). Parameters to describe the particle shape include sphericity, symmetry, convexity and aspect ratio. An essential characteristic of DIA is the extremely high detection sensitivity for oversized grains. The CAMSIZER® P4, for example, is designed to detect every single particle of a sample; the model CAMSIZER® X2 has a detection limit of 0.1 % for oversized particles. The resolution of DIA systems is also unbeatable: smallest size differences within the micrometer range are reliably detected and multimodal distributions are resolved without fail.

Figure 4. Measurement of a glass bead sample with DIA (CAMSIZER® P4, red) and sieve analysis (* black). The measurements can only be compared at the points which represent the sieve fractions. There is excellent agreement between the results. When taking a closer look at the data at 710 µm, it becomes apparent that the deviation of the Q3(x) value is 6 % which seems quite a lot at first sight. However, the deviation in size is only 13 µm and is thus within the tolerance of a 710 µm sieve which is ±25 µm. As the cumulative curve is very steep at this point, even a small difference in size has a strong impact on the Q3(x) value.

Figure 5. The image analysis system of the CAMSIZER® X2. The CAMSIZER® series uses patented dual camera technology with different resolutions to realise an extremely wide measuring range. The cameras capture the projections of the particles.

Figure 6. The DIA uses various size definitions to determine the particle size distribution. Consequently, one measurement can produce several distributions. In this example, the red curve is based on the measurement of particle width; the blue one represents particle length. The parameter X-area stands for the diameter of equivalent circle which is defined as the particle size. It depends on the original question which results are finally relevant. When examining fibres or extrudates, the length parameters are of interest; width is more important if comparison to sieve analysis is required.

If DIA is compared to sieve analysis, the particle ‘width’ is the common parameter. However, when measuring irregularly shaped particles there are still systematic differences in the obtained results due to the fact that DIA measures the particles in random orientation. Figures 2 and 3 illustrate for special particle shapes how the differences in the particle size measurement occur and how they can be interpreted. The differences in particle size distributions are systematic for each defined particle shape. The CAMSIZER® software features algorithms which allow to correlate the DIA results to almost 100% to those obtained by sieve analysis (Figure 7). This procedure is frequently applied in particle size analysis applications for quality control because in a globalised market many products are analysed by different laboratories with different measuring techniques, creating a need for comparability.

Figure 7. Example for the excellent agreement between measurement results of two sand samples obtained by DIA (red and blue curve) and sieve analysis (*).

Laser diffraction: Spheres and collectives With static laser light analysis, also called laser diffraction, particle size is measured indirectly by detecting intensity distributions of laser light scattered by particles at different angles. Figure 8 shows the set up of a modern laser granulometer such as Horiba’s LA-960. This technique is based on the phenomenon that light is scattered by particles and the correlation between intensity distribution and particle size is well-known. Simply put, large particles scatter the light to small angles while small particles produce large-angle scattering patterns. Whereas large particles produce rather sharp intensity distributions with distinctive maxima and minima at defined angles, the light scattering pattern of small particles becomes more and more diffuse and the overall intensity decreases. It is particularly difficult to measure differently sized particles in a polydisperse sample as the individual light scattering signals of the particles superimpose each other.

Static laser light scattering (SLS) is an indirect method which calculates particle size distributions on the basis of super-imposed scattered light patterns caused by a whole collective of particles. Algorithms are based on MIE theory with the assumption that particles are spherical and optical characteristics such as refraction index (RI) and absorption index (AI) are well known. A big advantage of SLS is the enormously wide measuring range; none of the other techniques presented here is able to reliably detect particles smaller than 1 micron. Analyses with SLS are easy to carry out and they can be automated to a large extent. A drawback of this method is the relatively poor resolution. Even the latest analyser generation cannot detect oversized fractions if the amount is below 2 Vol%. To resolve multimodal distributions the size of the two components involved needs to differ at least by factor 3. More than three different components in a mixture are basically not detectable. Figure 9 shows the example of a mixture of polystyrene-latex standard particles. In contrast to SLS, dynamic image analysis is capable of detecting exactly four different particle sizes whereas the laser diffractionanalyser cannot accurately resolve the 10 µm and 12 µm particles.

Figure 8. The laser light scattering spectrometer Horiba LA-960 uses two light sources and 93 measurement channels to record the scattered light pattern over a wide angle. It is possible to analyse suspensions, emulsions as well as dry powders in a measuring range from 0.01 m to 5,000 µm.

Figure 10 illustrates the comparability between SLS, DIA and sieve analysis using the example of ground coffee. Sieve analysis provides the finest results; the measurement of particle breadth with the CAMSIZER® X2 comes very close to this. There is no clear comparability between sieve analysis and laser diffraction; the result obtained with SLS corresponds roughly to the X-area parameter (diameter of equivalent circle). The various particle dimensions which are measured are all attributed to spherically shaped particles. Therefore, SLS always provides wider size distributions than image analysis.

This becomes even more apparent in Figure 11 which shows a measurement comparison of cellulose fibres. Whereas DIA distinguishes between the thickness and length of the fibres, SLS is not able to do so. The measurement curve of laser diffraction first runs parallel to the width measurement of DIA (red) and then approaches the ‘fibre length’ (blue). The result from laser scattering contains width and length information, all merged into one size distribution.

Figure 9. Measurement of a mixture of four particle standards (2.5 µm – 5 m – 10 µm – 12 µm). While DIA is able to distinguish the four components (red), laser diffraction identifies only three components.

Figure 10. Measurement of ground coffee with different methods. DIA, particle width (red); DIA, particle length (blue); DIA, diameter of the equivalent circle (green); laser diffraction (orange *); sieve analyses (black *).

Figure 11. Measurement of cellulose fibres. The CAMSIZER® XT (image analysis) measures particle breadth (red), particle length (blue), and X-area (green). The SLS measurement (*) is a mixture of breadth and length and shows a continuous transition. DIA can distinguish between breadth and length.

Conclusion

Of all the methods presented in this article, dynamic image analysis is the only technique capable of providing exact information about the particle size while also considering their shape. This means that it is possible to follow the results obtained by other methods and make them comparable, if required. Thanks to the direct measurement of particles, the information content and resolution of DIA are significantly superior to laser diffraction and sieve analysis.

The advantages of sieve analysis are the traditionally wide usage and the relatively cost-efficient equipment.

Particle size analysis by laser diffraction is the only method allowing for measurement in a size range below 1 micron.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)