Chromatography

Simplified, cost-effective headspace GC method for residual solvents analysis in pharmaceutical products

Aug 07 2019

Author: Giulia Riccardino and Cristian Cojocariu on behalf of Thermo Fisher Scientific (UK) Ltd

The aim of this work was to develop a rapid, cost-effective, modified USP <467> HS-GC-FID method for residual solvent determination in pharmaceutical products using the Thermo Scientific™ TriPlus™ 500 Headspace Autosampler and nitrogen as carrier gas.

Introduction

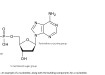

Organic solvents are often used in the manufacturing and purification of drug substances but due to their potential toxicity their absence/presence must be verified in the pharmaceutical products to ensure patient safety. The United States Pharmacopeia (USP) method <467> [1] provides detailed procedures for screening, confirmation and quantitation of residual solvents, including sample preparation and analytical conditions.

Gas chromatography (GC) coupled with headspace (HS) sampling technique and flame ionisation detection (FID) as detector is the analytical method specified in USP <467> for this application, as most of the target compounds are organic solvents with relatively low boiling points and good thermal stability.

Since a chromatographic resolution (Rs)≥1.0 between the critical pair acetonitrile/dichloromethane is required as a system performance criteria, an initial isothermal condition of the GC column followed by a slow heating rate is recommended by the USP <467> method, in order to avoid peak co-elution and to achieve a baseline peak separation. However, those conditions typically lead to a long analysis time (60 minutes).

The USP General Notices and Requirements [2] allows for the use of alternative methods but they shall be validated as described in the general chapter <1225> Validation of Compendial Procedures and must be shown to give equivalent or better results compared to the USP standard methods.

In this technical note, the USP <467> method for Class 2A solvent was modified as an example of how the residual solvent analysis can be improved with a faster and cost-effective alternative method.

Experimental

Sample preparation

USP <467> Class 2A residual solvent solution in dimethylsulfoxide (DMSO) was purchased from Restek® (P/N 36012). The stock solution was diluted in DMSO as reported in the USP method <467>, procedure A, water-insoluble articles. HPLC-MS grade water and GC headspace grade DMSO (purity ≥99.9%) were used as diluents. A representative test solution was prepared by diluting locally purchased common pain relief tablets (paracetamol, 500 mg and caffeine, 65 mg) in DMSO, as described in the regulation.

HS-GC-FID analysis

The TriPlus 500 Headspace autosampler was coupled to a Thermo Scientific™ TRACE™ 1310 Gas Chromatograph equipped with a Thermo Scientific™ Instant Connect Split/Splitless (SSL) Injector and a Thermo Scientific™ Instant Connect Flame Ionization Detector (FID).

Chromatographic separation was achieved on a USP G43 equivalent capillary column Thermo Scientific™ Trace GOLD™ TG-624 SilMS, 30 m x 0.32 mm x 1.8 μm column (P/N 26059-3390) using nitrogen as carrier gas. For this application, nitrogen is a viable alternative to helium (which is expensive and prone to regional shortage). Nitrogen allows for highly efficient GC separations and can easily be produced in the lab at high purity by using a nitrogen generator and making it very cost effective. Full instrumental conditions are given in Table 1.

Table 1. HS-GC-FID analytical parameters for Class 2A residual solvent screening according to the proposed USP <467> method modifications.

Data processing

Data was acquired and processed using Thermo Scientific™ Chromeleon™ Chromatography Data System (CDS) software, version 7.2, software compliant with the Federal Drug Administration Title 21 Code of Federal Regulations Part 11 (Title 21 CFR Part 11).

Results and discussion

The experiments aimed to improve the analytical method used for residual solvent analysis in pharmaceutical products, and as an example to demonstrate the utility of such method for Class 2A solvents. The ramp is too fast for Class 1. Benzene and 1,2-Dichloroethene co-elute. Furthermore, all the Class 1 RS elute in 10 minutes. The high thermal stability and superior inertness of the TG-624 SilMS capillary column allowed baseline separation for the critical pair acetonitrile/dichloromethane when a fast heating rate was applied, fulfilling the USP <467> resolution requirement with a short analysis time.

Class 2A standard solution at the concentration limits, as reported in Table 2, was injected into the chromatographic system.

Table 2. Concentration limits (ppm) for Class 2A residual solvents.

Applying a faster GC oven programming rate, the chromatographic separation of Class 2A residual solvents was achieved in less than 8 minutes (Figure 1) using nitrogen as carrier gas, as opposed to 60 minutes (with the UPS <467> default conditions), allowing for more than 7 times improvement in analysis speed without compromising chromatographic resolution and method performance. The TG-624 SilMS column allows for excellent chromatographic separation of target compounds, meeting (and significantly exceeding) USP <467> resolution acceptance criteria (Rs≥1.0).

Figure 1. Chromatographic separation for Class 2A residual solvent can be achieved in less than 8 minutes using a TG-624 SilMS capillary column and nitrogen as carrier gas. Rs for all residual solvent peaks is ≥1.0, in particular Rs between acetonitrile and dichloromethane met the regulation requirements with a calculated value of 2.3.

The test solution obtained by diluting common pain relief tablets was injected into the chromatographic system and screened for residual solvent content (Figure 1). No residual solvent peaks could be detected in the pharmaceutical sample, therefore USP <467> requirements for residual solvent content were met (this was in agreement with the same result when using the standard method shown elsewhere [4].

Obtaining repeatable data

Vial incubation oven, sample loop and sample path can be set at the same temperature, as the innovative design of the HS-GC direct interface ensures consistent analyte transfer, due to the higher inertness and shorter flow path compared to an external headspace transfer line. Moreover, the precise temperature control of the incubation oven and the effective vial shaking allows for a shorter incubation time (20 minutes) compared to the standard USP <467> method (60 minutes). Importantly, the results precision of target analytes was not affected by speeding up the analysis. This was demonstrated by assessing the absolute peak area repeatability obtained from n=12 consecutive injections of a Class 2A standard solutions at the concentration limits (Table 3). Average peak area %RSD was 1.1%, demonstrating a reliable and precise pneumatic control during sampling and injection.

Table 3. Peak area %RSDs obtained from n=12 consecutive analyses Class 2A residual solvents at the concentration limits described above (Table 2).

Conclusions

• Using the experimental conditions described, the modified USP <467> method is a real alternative to classical conditions for residual solvent analysis offering the advantages of:

- a rapid (x7 improvement in analysis speed); cost effective (with nitrogen as carrier gas).

- high throughput analysis (up to 240 samples analysed uninterrupted in a single sequence).

• Sample equilibration was reached in just 20 minutes as a result of the efficient vial agitation - a potential three times reduction in incubation time per sample.

• The TG-624 SilMS capillary column allowed for fast chromatographic separation of all Class 2A residual solvents in <8 minutes, exceeding the USP <467> chromatographic resolution requirement on the critical pair acetonitrile/dichloromethane (Rs=2.3).

• Reliable pneumatic control during sampling and injection, high inertness of the sample path and consistent analyte transfer through the HS-GC direct interface ensured excellent repeatability of the analyte peak area response, with average peak area %RSD=1.1% from n=12 consecutive vial analyses.

• Chromeleon CDS (compliant with the FDA Title 21 CFR Part 11 requirements) ensures data integrity, traceability, and effective data management allowing for easy and fast data processing, quantitation and reporting.

Taken together, the results from the experiments conducted show that method optimisation with nitrogen as carrier gas and TG-624 SilMS capillary column together with Chromeleon CDS represents a viable alternative for routine laboratories.

References

1. General Chapter USP <467> Organic Volatile impurities, Chemical Tests, United States Pharmacopeia, 2012

2. General Notices and Requirements USP <38>, United States Pharmacopeia, 2015

3. General Chapter USP <621> Chromatography, Physical Tests, United States Pharmacopeia, First Supplement to USP 40-NF 35, 2017

4. Thermo Fisher Scientific (2018) Residual Solvent Analysis Application Note: https://assets.thermofisher.com/TFS-Assets/CMD/Application-Notes/an-10676-hsgc-residual-solvents-pharmaceuticals-an10676-en.pdf

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)