Improve Acrylamide Analysis in Food with a Long-Lasting LC Column and a Cost-Effective Internal Standard

Acrylamide can form in food when sugars and the amino acid asparagine react during high-heat cooking processes like frying, roasting, grilling, or baking. Foods like potato chips/crisps, grain-based baked goods, and coffee are examples of commodities that have been focal areas for characterizing acrylamide presence and concentration. The detection of acrylamide in food was first reported in 2002 by the Swedish National Food Administration, and since then global efforts have been growing to better understand its origin in food and feed, the magnitude of contamination in various foodstuffs, and the potential health effects related to dietary exposure. Acrylamide is classified as a very hazardous chemical, and large quantities of it have been shown to cause cancer in laboratory animals (although no direct link between dietary exposure and increased incidence of cancer in humans has been proven to date). To safeguard public health, scientists need more efficient acrylamide methods that allow them to accurately determine concentrations in foods and beverages. Here, we compare typical approaches to acrylamide analysis in food to an improved process using an Allure Acrylamide column and deuterated internal standard. Benefits include faster analysis times and longer periods of sample throughput without system suitability failures.

Current Analytical Approach

LC-MS/MS is the Technique of Choice

Accurate acrylamide analysis in food matrices has presented technical challenges. Initially, GC separations with mass spectrometric detection techniques were pursued because acrylamide is a small and relatively volatile compound. However, those techniques relied on the conversion of acrylamide into a brominated derivative, which was an undesirable step [1]. LC-MS/MS techniques were explored and now are the most common analytical tool used in routine acrylamide analysis of food samples. LC-MS/MS methods still face analytical hurdles, most notably with the selective retention of acrylamide and its separation from compounds that are coextracted from the complex matrices typically being studied.

Use of Porous Graphitized Carbon (PGC) LC Columns

Europe has formalized a method for acrylamide analysis in food—EN 16618:2015—and it calls for the use of LC guard and analytical columns that contain porous graphitized carbon (PGC), in part because of the difficulty of analyzing acrylamide using more traditional reversed-phase (RP) retention mechanisms. PGC columns are now commonly used in the industry because they can retain acrylamide sufficiently to separate it from matrix components that may have been coextracted, even after the relatively rigorous EN method sample preparation procedure. The PGC column is also able to operate in 100% aqueous mobile phase, a condition under which many RP columns would undergo a phenomenon known as “dewetting,” which results in retention time loss and requires that the column be regenerated by a time-consuming flush with 100% organic mobile phase.

Use of Deuterated Internal Standards

Accurate quantitation is imperative, but the extraction process can introduce considerable variation, so the use of internal standards that are added to the sample along with the extraction solvent is recommended by the EN method. The EN method includes the use of deuterated internal standards instead of the carbon-labeled internal standards that have also been commonly used for acrylamide analysis. Significantly less expensive than carbon-labeled acrylamide, acrylamide-d3 is an excellent and cost-effective choice for internal standard.

Method Requirements

The time required for acrylamide analysis in food following method EN 16618:2015 is 8 minutes. To meet system suitability requirements, acrylamide must elute no earlier than 1.7 minutes, but the additional time spent after acrylamide elution is necessary to flush the column of matrix components that remained in the sample extract even after the two-step SPE sample preparation process outlined in the EN method. Matrix components are strongly retained on PGC columns, and if not sufficiently purged between analyses, can degrade performance to the point of failure to meet the 1.7-minute retention time system suitability requirement.

A Return to Reversed-Phase Retention Can Increase Sample Throughput

As labs approach the system suitability threshold when using PGC columns, they are faced with the choice to either conduct the lengthy column regeneration procedure in the hope that they regain the ability to meet system suitability criteria, or they have to replace the current guard, and possibly the analytical column. Both are time-consuming and costly propositions that halt sample throughput. Switching to an Allure Acrylamide column is a better alternative: the proprietary reversed-phase chemistry incorporates a unique polar ligand that retains acrylamide, is compatible with 100% aqueous conditions, and offers faster run times and longer column lifetimes than PGC columns. Using an Allure Acrylamide guard column and analytical column provides the best balance between retaining acrylamide long enough to meet the EN system suitability requirement, while not retaining coextracted matrix compounds so strongly that they cannot be flushed from the column quickly between analyses. As a result, labs using Allure Acrylamide columns can analyze more samples using fewer columns—a powerful savings combination for any food safety lab. The following examples illustrate the benefits of using an Allure Acrylamide column and guard, along with a deuterated internal standard, for high-throughput food safety labs.

Shorter Analysis Times

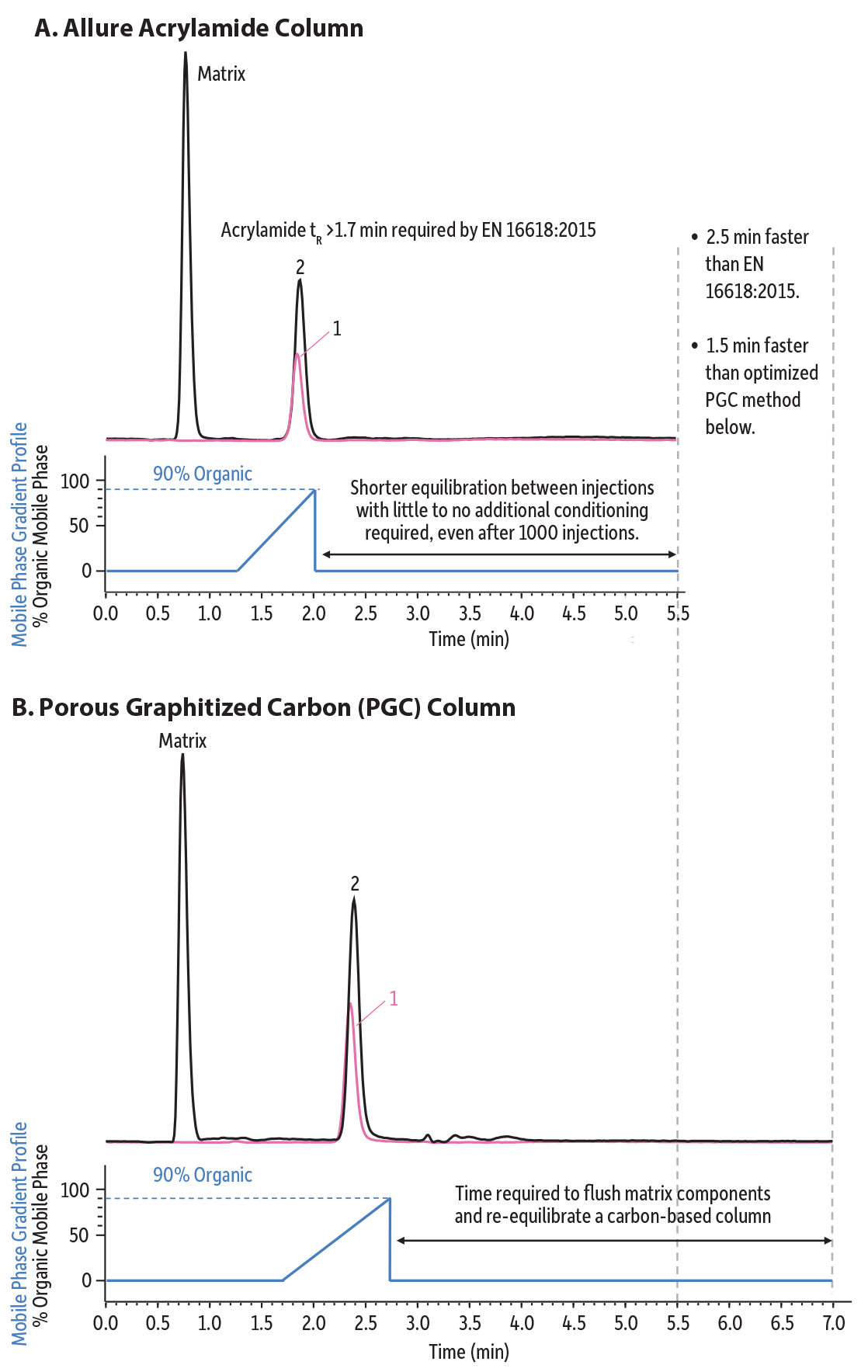

Because matrix compounds elute quickly from the Allure Acrylamide column, it is able to equilibrate and be ready for the next injection faster than even a PGC column run under optimized conditions. Figure 1 shows an example of two different methods for acrylamide analysis in food (potato chips in this case), one with an Allure Acrylamide column and one with a representative PGC column. The PGC column method was further optimized from the EN method, shortening the analysis time from 8 to 7 minutes, while still providing the optimal column flushing and equilibration time. Any further flushing provided no significant benefit to column lifetime. The acrylamide analysis on the Allure Acrylamide column met the method requirement of 1.7-minute retention with good separation from matrix components, but with much shorter equilibration times. A per analysis savings of 2.5 minutes compared to EN 16618:2015 and 1.5 minutes compared to the optimized PGC column method, allows more samples to be analyzed per shift, increasing lab output.

Figure 1: Labs can increase sample throughput using an Allure Acrylamide column because much less equilibration time is needed compared to an PGC column, even with a complex matrix like potato chips.

Longer Column Lifetimes

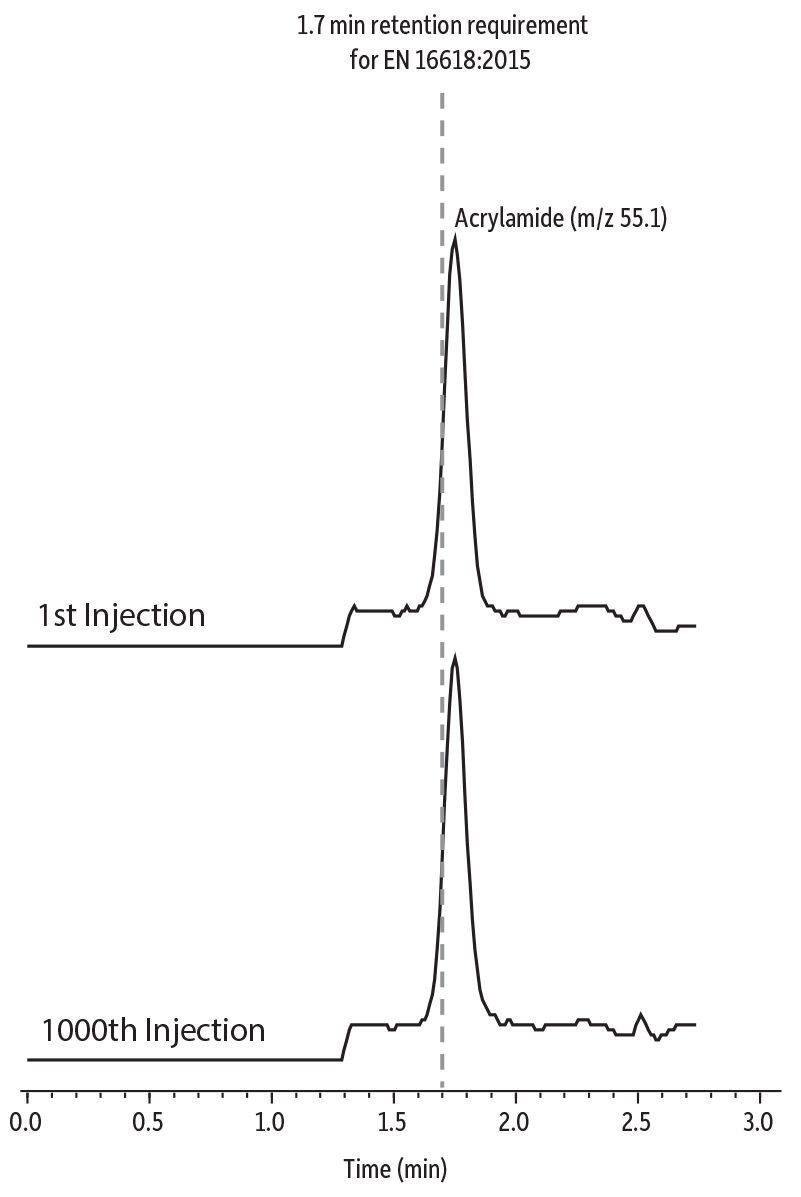

Figure 2 illustrates the extreme stability of acrylamide retention time achieved with the Allure Acrylamide column compared to a representative PGC column, which shows loss of retention almost immediately and ultimately fails the 1.7 minute retention time requirement after 475 injections of a coffee sample, extracted and cleaned up per EN 16618:2015. In contrast, even after 1000 injections, the Allure Acrylamide performance remains steady and ready for the next injection. Figure 3 shows how the chromatography remains unaffected from the first to the thousandth injection on the Allure Acrylamide column. Its ability to elute coextracted matrix compounds rather than strongly retain them is the key to its extremely stable performance over hundreds and hundreds of repeat matrix injections with little to no column maintenance.

Figure 2: The Allure Acrylamide column still meets EN 16618:2015 system suitability requirements even after 1000 injections—over twice as many passing injections than a typical PGC column.

Figure 3: Even after 1000 injections of coffee extract, without any system maintenance or guard column replacement, the Allure Acrylamide column performance remains unchanged.

Consistent Column-to-Column Performance

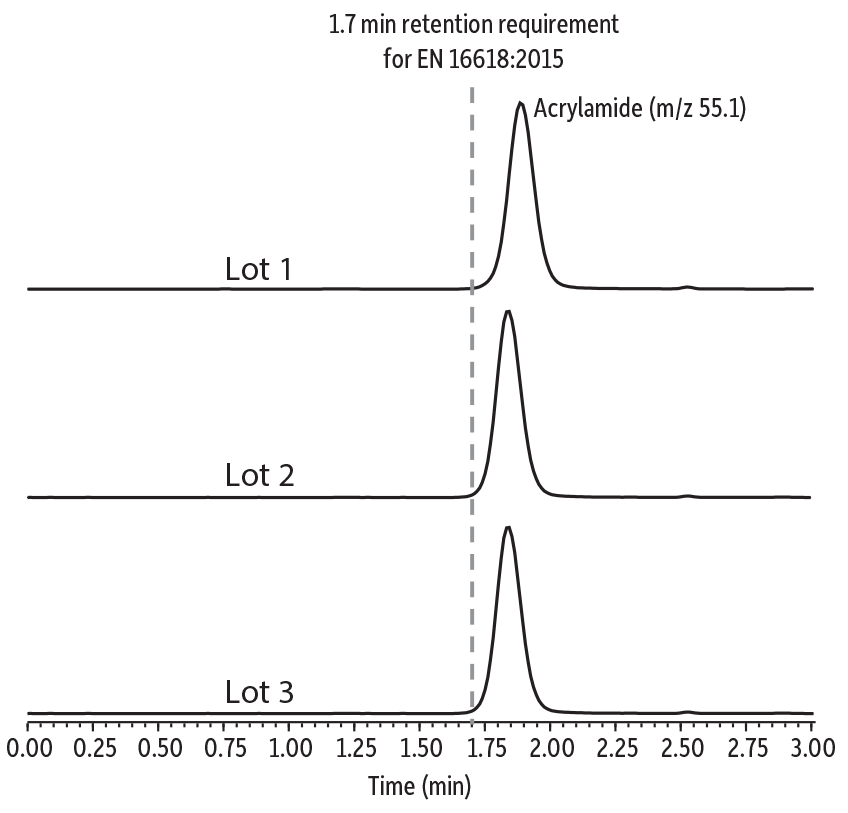

Developed to withstand 100% aqueous mobile phases, Restek Allure Acrylamide guard and analytical columns deliver the same robust performance injection to injection, and also column to column. Our stringent manufacturing procedures and rigorous quality testing ensure that when it does come time to replace your Allure Acrylamide column, you’ll get the same acrylamide analysis performance with the new column that you relied on with the old one (Figure 4).

Figure 4: Rugged reversed-phase Allure Acrylamide LC columns deliver reproducible results column to column and lot to lot.

A Better Solution for Acrylamide Analysis in Food

While the PGC columns used in EN 16618:2015 do sufficiently retain acrylamide, their strong retention of coextracted matrix components requires long equilibration times and shortens column lifetime. Faster overall acrylamide analysis can be achieved using Allure Acrylamide columns because they ensure sufficient retention of acrylamide, while allowing matrix compounds to be flushed out more efficiently and effectively. As a result, method system suitability requirements can be maintained over more injections, allowing more samples to be analyzed before maintenance is needed. Pairing Allure analytical columns and guard cartridges with a deuterated internal standard allows labs to increase productivity and profitability by analyzing more samples, in less time, with fewer columns.

References

- J.A.G. Roach, D. Andrzejewski, M.L. Gay, D. Nortrup, S.M. Musser, Rugged LC-MS/MS survey analysis for acrylamide in foods, J. Agric. Food Chem. 51 (2003) 7547−7554. https://pubs.acs.org/doi/abs/10.1021/jf0346354