Latest News

Electrodes for Potable Water Treatment Offer Savings of £1 Million per Year

REFEX (Ireland) has supplied Irish water companies with the EC-3/4″-2001-Pt1000-LE all in one combination electrode for use in 120 pH measurement systems. Compatible with all

What is Refex?

REFEX reference junctions are manufactured from an electrochemically conductive, salt loaded, polymeric matrix. When installed in an electrode, there is no porous junction to allow liquid contact between process fluids and the internal (sealed for life) Ag/AgCl reference half-cell. REFEX provides a stable mV output for measurement and ensures that process fluids do not poison or deplete reference cell electrode or electrolyte

REFEX continues to perform even when completely coated as long as the coating remains wet and is conductive. Even when severe coating of the sensor inevitably slows electrode response, pH measurement remains accurate. Proven applications range from clean, cold river water to crude oil, sewage sludge and nasty chemical streams – all are solved with a REFEX reference interface.

The REFEX electrode is the reliable sensor the market has been waiting for – almost maintenance free with exceptionally long life and superb stability.

All REFEX reference sensor separates and combination probes are built using REFEX reference junction technology and have these very real benefits

The Issue With Existing Sensors

Refex products represent a revolutionary advance in pH and ORP measurement technology that solves the key weakness of the reference electrode in traditional probe designs. These traditional designs depend upon having a porous junction to provide electrochemical connection between the probe’s reference electrode and the process flow being measured. This necessary contact with process fluid allows interaction with the [stable] internal liquid in the reference half-cell, commonly diluting and/or poisoning it and causing measurement drift while leading to eventual sensor failure. In harsh applications, this interaction can lead to rapid failure.

The Refex Solution

Advantages of Refex non-porous sensors:

- Resistant to fouling and poisoning

- Protected Ag/AgCl reference half-cell – Refex barrier/interface prevents all liquid contact/exchange.

- Resistant to high and changing temperatures between 0 – 100°C

- Resistant to high and changing pressures between full vacuum and 20 bar pressure.

- Instant response to pH change

- Constant Eo zero – no continuous drift over time

- Long, long electrode life – many times longer than all others

- Compatible with all standard, modern pH instruments with dual high impedance inputs

- No diffusion potential errors in low ionic water applications

- No KCl electrolyte loss due to dilution

- No refilling of KCl electrolyte – sealed for life.

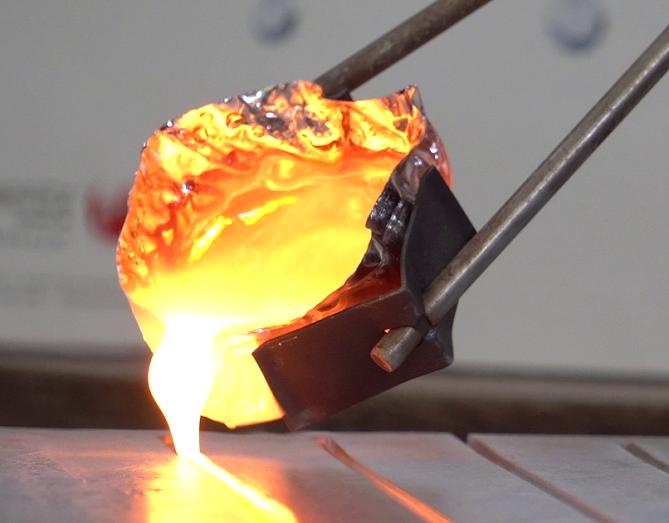

The Production Process

REFEX™ pH Sensors manufacture many varied pH sensor types, for many industrial processes, and for general purpose applications. Check out our video which shows the Refex production process and explains how Refex can help save your company money.

Products

See Our Range Of Products